Welding Air Bag

Welding Air Bag – Ultrasonic Welding – Cheersonic

An airbag is a vehicle occupant-restraint system using a bag designed to inflate extremely quickly, then quickly deflate during a collision. It consists of the airbag cushion, a flexible fabric bag, an inflation module, and an impact sensor. The purpose of the airbag is to provide a vehicle occupant with a soft cushioning and restraint during a crash event. It can reduce injuries between the flailing occupant and the interior of the vehicle. The air bag is sewn from a woven nylon fabric and can come in different shapes and sizes depending on specific vehicle requirements. The driver’s-side air bag material is manufactured with a heat shield coating to protect the fabric from scorching, especially near the inflator assembly, during deployment. At the meantime, vehicles can be equipped with both front and side air bags.

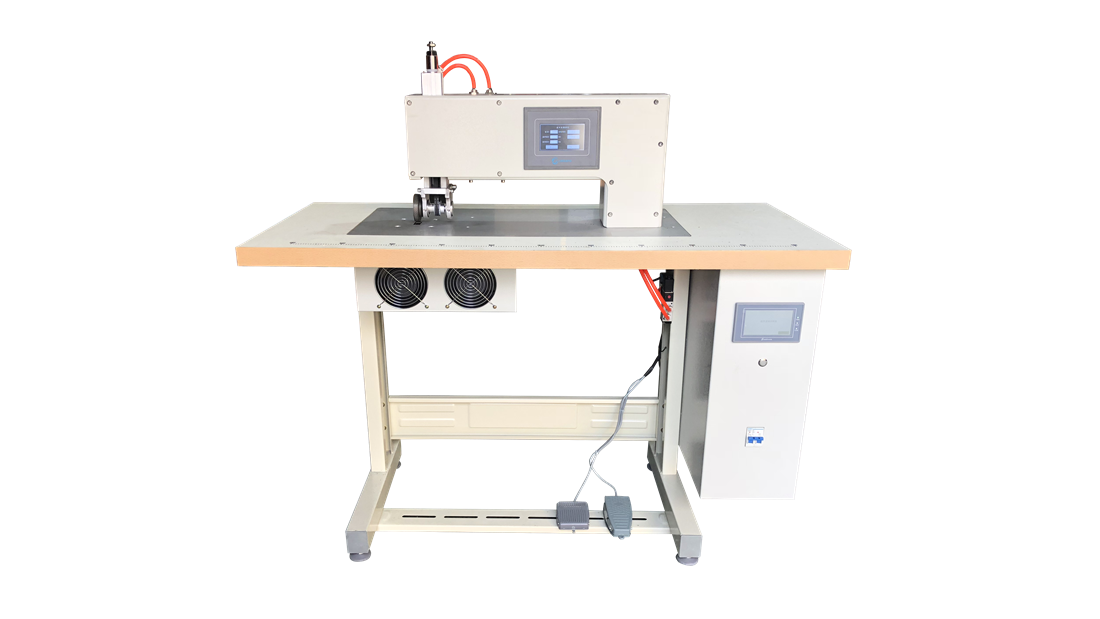

Ultrasonic welding means the cohesive bonding of thermoplastic fabrics through internal friction, heating and fusion of the material. The ultrasonic sewing technology is a modern, innovative and economic alternative and complementary to conventional sewing technology. Workpiece is held between the sonotrode and the anvil wheel and welded continuously under pressure. Ultrasonic energy provides savings, efficiency and clean production opportunities in the area where it is used. The ultrasonic sewing technology is widely used in producing air bag. After repeated testing, CHEERSONIC has cooperated with airbag production enterprise, developing the optimal sealing side airbag equipment, ultrasonic sealing side.

Cheersonic is an expert manufacturer of ultrasonic equipment. We have focused on ultrasonic sewing technology more than 20 years. The ultrasonic technology and automated system are researched and developed all by ourselves. In our sample and testing studio we are offering the testing of your material. According to the needs and testing result, Cheersonic would customize ultrasonic solutions for you.