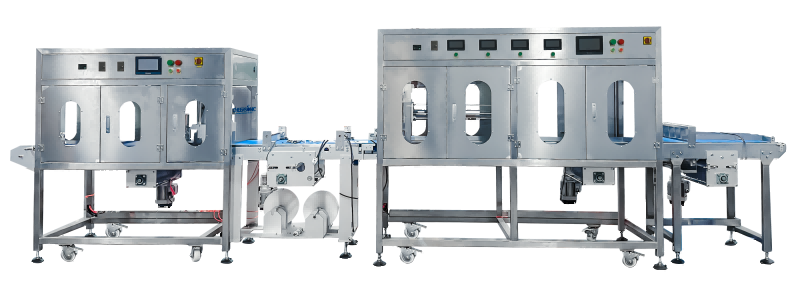

Ultrasonic Swiss Roll Cutting and Packaging Equipment

In the food industry, cutting and packaging have always been an important part of ensuring product quality and appearance. For Swiss rolls, a sponge cake that is popular among consumers, the traditional cutting method is not only inefficient, but also difficult to ensure the accuracy and beauty of the cutting. However, with the advancement of science and technology, the introduction of ultrasonic technology has brought revolutionary changes to the cutting and packaging of Swiss rolls. This article will introduce the ultrasonic Swiss roll cutting and packaging machine and its significant advantages in detail.

1. Introduction to ultrasonic Swiss roll cutting and packaging equipment

The ultrasonic Swiss roll cutting and packaging machine is an advanced equipment that integrates ultrasonic cutting technology and automated packaging technology. It uses the high-frequency vibration of ultrasound to generate tiny vibrations between the cutting tool and the food material, thereby achieving fast and accurate cutting. At the same time, the equipment is also equipped with an automated packaging system that can automatically complete the packaging of Swiss rolls according to preset parameters.

2. Advantages of ultrasonic Swiss roll cutting and packaging equipment

High efficiency and speed: Ultrasonic cutting technology can achieve high-speed cutting, greatly improving production efficiency. Compared with traditional cutting methods, ultrasonic cutting is faster and can complete the cutting of a large number of Swiss rolls in a short time.

- High precision: Since ultrasonic cutting is achieved through high-frequency vibration, the cutting lines are smoother and more precise. This not only ensures that each layer of the Swiss roll maintains a perfect shape and taste, but also reduces waste and improves the utilization rate of raw materials.

- Hygiene and safety: The ultrasonic cutting machine will automatically clean after a single operation to ensure that no bacteria or contaminants are introduced during the cutting process. At the same time, since no heat and smoke are generated during the cutting process, it will not contaminate the food, ensuring the hygienic safety of the food.

- High degree of automation: The ultrasonic Swiss roll cutting and packaging machine has a high degree of automation and can achieve unattended continuous production. This not only reduces labor costs, but also improves production efficiency and product quality.

- Versatility: Ultrasonic cutting technology has a wide range of applications. In addition to Swiss rolls, it can also be used to cut other types of pastries, bread and other foods. At the same time, the equipment can also be customized according to actual needs to meet the personalized needs of different customers.

In short, the emergence of ultrasonic Swiss roll cutting and packaging machines has brought revolutionary changes to the food industry. It not only improves the cutting efficiency and accuracy of Swiss rolls, but also ensures the hygienic safety and production efficiency of food. With the continuous development of science and technology, I believe that ultrasonic technology will play a more important role in the food industry in the future.

About Cheersonic

Cheersonic manufactures the leading portioning equipment for bakeries producing fresh and frozen desserts. Since 1998 bakers have used Cheersonic machines to cut, slice and portion cheesecake, pie, layer cake, loaves, butter, cheese, pizza, sandwichs, and more. Cheersonic offers ultrasonic cutting solutions that support start-up bakeries and high production commercial facilities alike. Small standalone machines can be used in manual baking facilities and large inline robotic solutions aid in high speed production.

Cheersonic offers many ultrasonic slicing models, both inline and offline applications, with production speeds of 80 to 1,500 cakes or pies per hour.

Cheersonic’ latest offline introductions include ultrasonic cutting with or without divider inserts between each slice. This improves the quality of the cut and makes for a much better product presentation for the customer. In addition, robotic arm improves the speed, efficiency, and accuracy of the cutting process, producing professional looking products every time.

Chinese Website: Cheersonic Provides Professional Ultrasonic Cutting Solutions