Ultrasonic Spraying Technology For Fuel Cells

Comparison between ultrasonic spraying technology and traditional coating technology

Traditional coating methods have many limitations for coating applications in fuel cells. With dip coating technology, it is difficult to control the thickness and uniformity of the coating at the same time. Air atomizing spray valve will produce too much spray, easy to block, produce non-uniform spray form, and it is difficult to maintain accurate control of liquid flow rate; screen printing technology is suitable for coating thicker coatings without thin coatings. Layer ability; manual brushing technology is inherently subjective as it tests the skills of the operator.

Advantages of ultrasonic spraying technology:

• High spray uniformity and controllability

• Not easy to block the nozzle

• High raw material utilization and reduced waste

• No need for high pressure gas

• Raw material usage rate exceeds 95%

• Touch screen control system

• High-precision laboratory syringe pump

Recommended Equipment

Ultrasonic Atomization Nozzle

Laboratory Ultrasonic Coating System

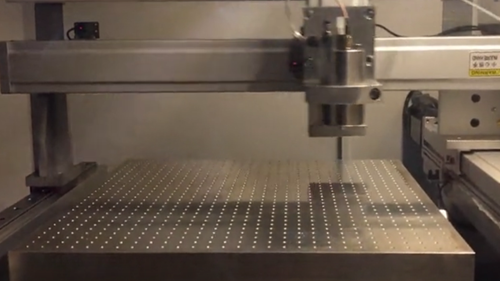

Desktop Ultrasonic Spraying Machine

Desktop Ultrasonic Precision Spraying Machine

Medium Ultrasonic Spraying Machine

Ultrasonic Stent Coating System

Ultrasonic Balloon Coating Equipment

Inline Ultrasonic Coating System

UAL100 Ultrasonic Dispersion Syringe Pump

LULP500 Ultrasonic Laboratory Device

Prosonic1000 Industrial Ultrasonic Device

Prosonic3000 Most Powerful Ultrasonic Processor