Ultrasonic Spraying Machine for Electrolyzer Coatings

With the rapid development of hydrogen energy, proton exchange membrane electrolysis of water for hydrogen production has become a research hotspot. Ultrasonic spraying machine, as an advanced coating preparation technology, plays an important role in the spraying process of proton exchange membrane electrolyzer. This article aims to explore the application of ultrasonic spraying machine in proton exchange membrane electrolysis water hydrogen electrolyzer and its impact on hydrogen production efficiency.

Hydrogen energy is known as the “ultimate energy” of the 21st century, with advantages such as cleanliness, efficiency, and storability. The proton exchange membrane electrolysis of water for hydrogen production technology has attracted much attention due to its high energy conversion efficiency and environmental friendliness. As the core equipment for proton exchange membrane electrolysis of water to produce hydrogen, the performance of the electrolyzer directly affects the efficiency of hydrogen production. The application of ultrasonic spraying machine in the preparation of electrolyzer coatings provides a new idea for improving the performance of electrolyzers.

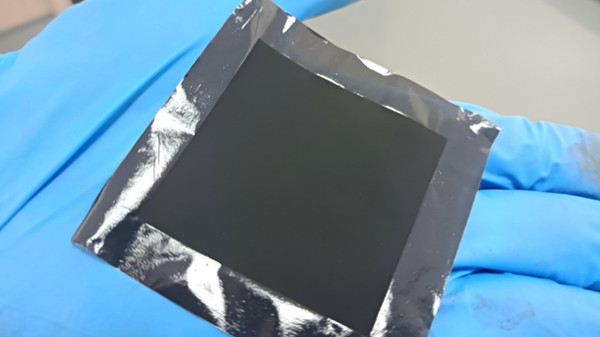

The ultrasonic spraying machine uses high-frequency vibration of ultrasonic waves to atomize the coating into fine particles, and uniformly sprays the coating on the surface of the proton exchange membrane electrolyzer through airflow, forming a uniform and dense coating.

Advantage

- Uniform spraying: Ultrasonic spraying machines can achieve efficient atomization of coatings, ensuring uniform and dense coating.

- Strong adhesion: Ultrasonic spraying technology makes the coating bond more tightly with the substrate surface, improving the adhesion of the coating.

- Energy saving and environmental protection: The high utilization rate of coatings reduces coating waste and environmental pollution.

Application of Ultrasonic Spray Machine in Proton Exchange Membrane Electrolysis of Water and Hydrogen in Electrolyzer

- Improve the performance of the electrolyzer

The coating prepared on the surface of proton exchange membrane electrolyzer using ultrasonic spraying machine has good conductivity and chemical stability, which is conducive to improving the hydrogen production efficiency and service life of the electrolyzer. - Optimize the structure of the electrolyzer

Ultrasonic spraying machine can spray according to the complex structure of the electrolyzer, effectively improving the coverage of the coating on key parts such as anode and cathode, diaphragm, and reducing the internal resistance of the electrolyzer - Reduce energy consumption

The coating prepared by ultrasonic spraying mechanism has good insulation performance, reducing heat loss during the electrolysis process and thus lowering the energy consumption of the electrolyzer.

The application of ultrasonic spraying machine in proton exchange membrane electrolysis water hydrogen electrolyzer provides strong guarantee for improving the performance and hydrogen production efficiency of the electrolyzer. With the rapid development of the hydrogen energy industry, the application prospects of ultrasonic spraying technology in the field of electrolyzer manufacturing will be even broader. In the future, China should continue to increase research and promotion of ultrasonic spraying technology, promote the progress of proton exchange membrane electrolysis of water for hydrogen production technology, and help the hydrogen energy industry achieve sustainable development.

About Cheersonic

Cheersonic is the leading developer and manufacturer of ultrasonic coating systems for applying precise, thin film coatings to protect, strengthen or smooth surfaces on parts and components for the microelectronics/electronics, alternative energy, medical and industrial markets, including specialized glass applications in construction and automotive.

Our coating solutions are environmentally-friendly, efficient and highly reliable, and enable dramatic reductions in overspray, savings in raw material, water and energy usage and provide improved process repeatability, transfer efficiency, high uniformity and reduced emissions.

Chinese Website: Cheersonic Provides Professional Coating Solutions