Ultrasonic Spraying Fuel Cell Membrane Electrode

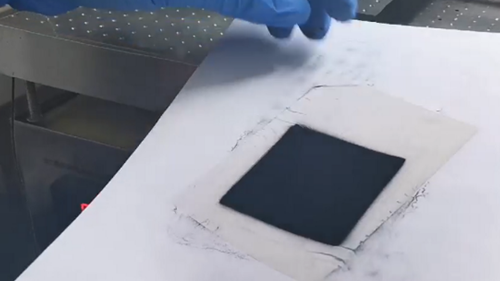

Ultrasonic spraying technology can prepare carbon-based catalyst coatings with high uniformity and high density, such as depositing platinum carbon, palladium carbon, ruthenium carbon and other catalyst coatings on Nafion proton exchange membranes, which are dense and uniform without swelling. Therefore, the ultrasonic spraying technology has been widely regarded by the industry as the key preparation technology of the membrane electrode of the proton exchange membrane fuel cell. Ultrasonic spraying equipment can be sprayed on a variety of different metal alloys, including the preparation of platinum, nickel, iridium and ruthenium-based fuel cell catalyst coatings, as well as PEMs, GDLs, DMFCs (direct methanol fuel cells) and SOFCs (solid oxide fuels) Battery). The battery manufactured by this technology has the characteristics of high battery load and high battery efficiency.

Cheersonic ultrasonic coating systems are used to apply precision thin film coatings to parts and components in the microelectronics/electronics, alternative energy, medical and industrial markets (including special glass applications in the construction and construction industry) to protect, strengthen or smooth surfaces.

The ultrasonic coating system is environmentally friendly, efficient and highly reliable, which can greatly reduce overspray, save raw materials, and improve process repeatability, transfer efficiency, high uniformity and reduce emissions.