Ultrasonic Spraying Fuel Cell Catalyst

In spite of many efforts and improvements by thousands of scientists worldwide, PEMFCs and DMFCs have not been commercially used. State-of-the-art electrocatalysts for PEMFCs rely on large quantities of platinum to achieve acceptable performance levels. This presents a significant hurdle to market acceptance of FC-powered vehicles; a commercially viable electrocatalyst will require nearly an order-of-magnitude reduction in Pt usage to meet both cost and Pt availability constraints. Pt fine particles are dispersed on carbon blacks with a large surface area to reduce the total Pt used and to enhance catalytic activity. This activity depends not only on the primary structure of the catalyst Pt/carbon composites (i.e., carbon surface area, Pt particle size, Pt surface area, etc.), but also on the secondary structure (i.e., aggregation and agglomeration of carbon grains).

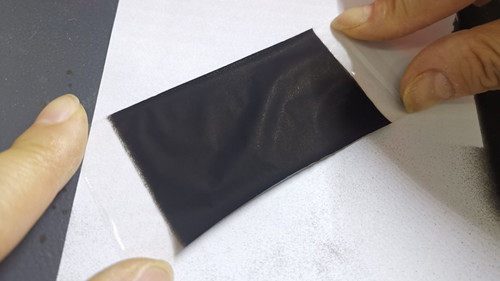

Ultrasonic Spraying Fuel Cell Catalyst. Research has proven Platinum utilization in membranes coated using ultrasonic spray is approximately 90%. Ultrasonic vibrations continuously break up agglomerated particles and keep them evenly dispersed; maximizing platinum utilization. Up to 50% reduction in material consumption with reduced overspray, conserving expensive catalyst inks.

Thin films By Ultrasonic Spray Pyrolysis Video

Recommended Equipment

Ultrasonic Atomization Nozzle

Laboratory Ultrasonic Coating System

UAM3000 Ultrasonic Medical Devices Spraying

UAM4000 Desktop Ultrasonic Spraying Equipment

UAM4000L Benchtop Ultrasonic Spray System

UAM6000 Ultrasonic Spraying Machine

UAL100 Ultrasonic Dispersion Syringe Pump

LULP500 Ultrasonic Laboratory Device

Prosonic1000 Industrial Ultrasonic Device

Prosonic3000 Most Powerful Ultrasonic Processor