Ultrasonic Spraying Equipment For Proton Exchange Membrane

Ultrasonic Spraying Equipment For Proton Exchange Membrane – Cheersonic

Ultrasonic spraying technology has shown great potential in the preparation and modification of proton exchange membranes (PEM) due to its unique process advantages. This technology not only improves the performance and stability of proton exchange membranes, but also reduces preparation costs and energy consumption, making it an innovative method in the production process of modern energy conversion equipment.

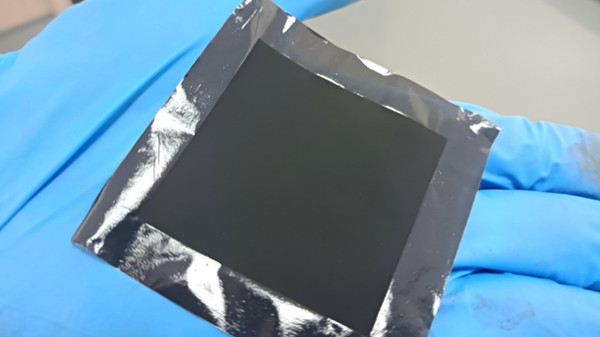

The ultrasonic spraying equipment, which adopts the national patent technology, can meet the needs of small and medium-sized batch production, and is especially suitable for preparing uniform and dense film coatings and spray pyrolysis. This device can atomize sprayed materials into extremely fine particles through ultrasonic energy, forming a uniform and fine coating, which is crucial for improving the performance of proton exchange membranes.

During the preparation and modification process of PI proton exchange membrane by ultrasonic spraying, its unique advantages were demonstrated. It not only improves the performance and stability of proton exchange membranes, but also reduces preparation costs and energy consumption. The continuous development and improvement of ultrasonic spraying technology is expected to play a more important role in the field of proton exchange membranes, promoting the performance improvement and green sustainable development of energy conversion equipment such as fuel cells.

Ultrasonic spraying technology has shown great potential for application in proton membrane coating processes. It not only revolutionizes traditional coating methods, but also improves efficiency and uniformity, opening up new paths for the development of clean energy technology. The application of this technology helps to improve production efficiency, reduce material waste, and maintain the environmental friendliness of the production process.

The working principle of ultrasonic spraying equipment is to use ultrasonic spraying to spray proton exchange membranes, ensuring the high uniformity of the catalyst layer and the uniform dispersion of suspended particles. This can achieve highly efficient coating of electrolytic cells, whether single-sided or double-sided. For example, ultrasonic nozzle technology can provide uniform and efficient thin film spraying, with high precision in coating thickness control, spray uniformity exceeding 95%, and significantly improved solution conversion rate.

Overall, ultrasonic spraying equipment has significant advantages in spraying proton exchange membranes. This technology can not only improve the uniformity and adhesion of coatings, but also improve production efficiency and reduce costs by reducing raw material loss and environmental pollution. With the further development of technology and the expansion of market applications, ultrasonic spraying equipment will play an increasingly important role in the production of proton exchange membranes and other related fields.

About Cheersonic

Cheersonic is the leading developer and manufacturer of ultrasonic coating systems for applying precise, thin film coatings to protect, strengthen or smooth surfaces on parts and components for the microelectronics/electronics, alternative energy, medical and industrial markets, including specialized glass applications in construction and automotive.

Our coating solutions are environmentally-friendly, efficient and highly reliable, and enable dramatic reductions in overspray, savings in raw material, water and energy usage and provide improved process repeatability, transfer efficiency, high uniformity and reduced emissions.

Chinese Website: Cheersonic Provides Professional Coating Solutions