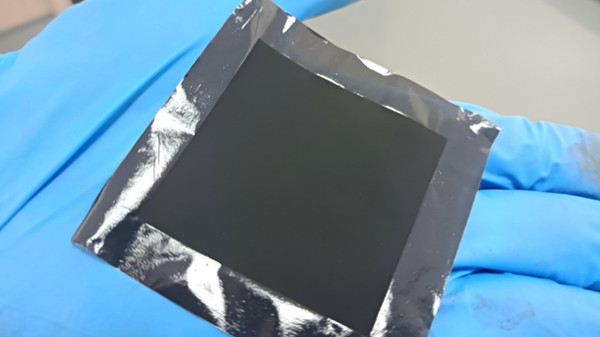

Ultrasonic Spray Water Electrolysis Membrane Electrode

Ultrasonic spraying has the following characteristics and benefits for water electrolysis membrane electrodes:

1. Characteristics: High coating uniformity: Ultrasonic spraying can refine the coating into tiny particles and deposit them evenly on the electrode surface, achieving coating accuracy at the micrometer or even nanometer level. This makes the distribution of catalysts, electrolytes, and other materials on the electrode surface very uniform, which helps to improve the performance and stability of the electrode.

- Low impact on the membrane: During the spraying process, it will not cause deformation or damage to the proton exchange membrane, ensuring the structural integrity of the membrane electrode.

- Suitable for various materials: It can be used to spray spray suspensions containing carbon black ink, PTFE adhesive, ceramic slurry, platinum and other precious metals, as well as other metal alloys and metal oxide suspensions, to meet the different needs of water electrolysis membrane electrode preparation.

2. Benefits: Improved performance: Uniform coating can enhance the catalytic activity and conductivity of the electrode, reduce the resistance to proton transfer, and thus improve the efficiency and effectiveness of water electrolysis. And a thin and uniform coating helps to improve the performance of fuel cells. Similarly, for water electrolysis membrane electrodes, it can enhance their reactivity and stability during the water electrolysis process.

- Cost reduction: The utilization rate of precious metals such as platinum in the membrane sprayed by ultrasound is relatively high, reaching about 90%, which reduces material consumption and saves the use of expensive catalyst ink, thereby reducing the manufacturing cost of water electrolysis membrane electrodes.

- Energy saving and environmental protection: Compared with traditional coating methods, ultrasonic spraying does not require high-pressure air, reducing the rebound and splashing of the coating and improving the utilization rate of the coating; At the same time, this technology does not require the use of organic solvents, reducing the generation of waste and environmental pollution, which meets the requirements of modern industry for energy conservation and environmental protection.

- Improving preparation efficiency: Ultrasonic spraying equipment has the characteristics of speed and efficiency, which can complete the coating of large-area electrodes in a short time, greatly improving the preparation efficiency of membrane electrodes and shortening the process cycle.

- Enhanced coating performance: The action of ultrasound promotes the bonding between the coating and the substrate during the coating process, enhancing the adhesion and bonding strength of the coating, making the electrode have better wear resistance and corrosion resistance, and extending the service life and stability of the electrode

The application of ultrasonic spraying in water electrolysis membrane electrodes mainly includes:

- Hydrogen production by water electrolysis: In a proton exchange membrane (PEM) electrolysis tank, carbon based catalyst ink is sprayed onto the electrolyte membrane to manufacture efficient water electrolysis membrane electrodes for the production of green hydrogen gas.

- Fuel cell: Used for the preparation of membrane electrodes in fuel cells, improving the performance and lifespan of fuel cells, and promoting the commercial application of fuel cells.

- Scientific research experiments: Suitable for the research and development of water electrolysis membrane electrodes and the preparation of small batch thin film coatings in the laboratory, facilitating researchers to conduct relevant experimental research and technological development.

About Cheersonic

Cheersonic is the leading developer and manufacturer of ultrasonic coating systems for applying precise, thin film coatings to protect, strengthen or smooth surfaces on parts and components for the microelectronics/electronics, alternative energy, medical and industrial markets, including specialized glass applications in construction and automotive.

Our coating solutions are environmentally-friendly, efficient and highly reliable, and enable dramatic reductions in overspray, savings in raw material, water and energy usage and provide improved process repeatability, transfer efficiency, high uniformity and reduced emissions.

Chinese Website: Cheersonic Provides Professional Coating Solutions