Ultrasonic spray pyrolysis deposited electrolyte layers

The growing energy demand in the world requires a major shift to more efficient energy conversion with large-scale energy storage. Many new technologies are currently being developed in this area. The advantage of solid fuel cells is that they can efficiently produce electricity and heat from different fuels (such as methane, landfills, and syngas). Due to the relatively high operating temperature of the device (800-1000ºC), the full commercialization of the technology has been delayed due to the short life and high cost.

One strategy to improve the profitability of solid oxide fuel cells is to reduce their operating temperature to a medium range (600-800 ° C). Unfortunately, classic zirconia-based electrolytes have low ionic conductivity at reduced temperatures. In addition, the high chemical reactivity between zirconia electrolytes and some rare earth cobalt ion cathodes is problematic at moderate temperatures. Although some cation diffusion has occurred, the doped cerium oxide interlayer has been used as a chemical barrier between the components. Electrolytes based on cerium oxide and barium cerate have been proposed as alternatives to zirconia. Unfortunately, the oxide ion conductor in cerium oxide exhibits undesired electronic conductivity in the reducing medium, while the proton-conductive ceramic barium-cerium exhibits stability problems in a CO 2 environment.

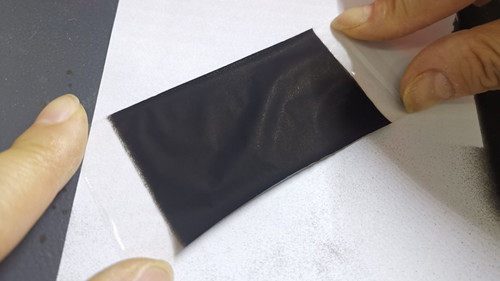

In this work, in view of these problems, the performance of protective layers deposited by low-cost ultrasonic spray pyrolysis was studied. It was found that low concentrations of co-doped co cations can reduce the harmful electronic conductivity of cerium oxide under reducing conditions. The optimally heat-treated cerium oxide and zirconium protective coatings effectively reduced cation diffusion and improved the CO2 tolerance of the barium-serum electrolyte.

Proton Exchange Membrane Coating Spray Video

Recommended Equipment

Ultrasonic Atomization Nozzle

Laboratory Ultrasonic Coating System

UAM3000 Ultrasonic Medical Devices Spraying

UAM4000 Desktop Ultrasonic Spraying Equipment

UAM4000L Benchtop Ultrasonic Spray System

UAM6000 Ultrasonic Spraying Machine

UAL100 Ultrasonic Dispersion Syringe Pump

LULP500 Ultrasonic Laboratory Device

Prosonic1000 Industrial Ultrasonic Device

Prosonic3000 Most Powerful Ultrasonic Processor