Ultrasonic Spray Coaters for Proton Exchange Membrane

Ultrasonic spray coaters for proton exchange membrane has multiple advantages and characteristics. The following is a specific introduction:

1. Working principle:

- Ultrasonic spraying equipment mainly converts high-frequency sound waves into mechanical energy through piezoelectric transducers, and then transmits the mechanical energy into the liquid. This longitudinal vibration generates standing waves in the application of ultrasonic nozzles in liquid films, and the amplitude of the waves can be controlled by a power generator. When the droplets leave the atomization surface of the nozzle, they are decomposed into a uniform fine mist of micrometer or even nanometer sized droplets, which are then uniformly sprayed onto the proton exchange membrane.

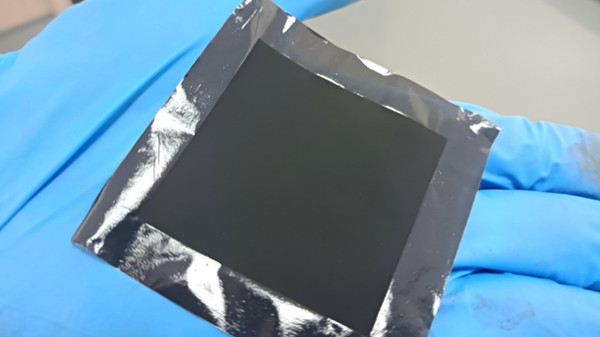

- High uniformity of coating: Ultrasonic spraying can produce very small and uniform droplets, which can evenly distribute the coating on the surface of the proton exchange membrane. This is crucial for the performance of proton exchange membranes, as a uniform coating can ensure efficient proton transport and improve the efficiency and performance of fuel cells or electrolysis cells.

- High material utilization rate: The droplet size is uniform and the spraying process is precise and controllable, which can reduce the waste of coatings. Compared with traditional spraying methods, it can save a lot of coating materials and reduce production costs.

- Minimal damage to the membrane: Ultrasonic spraying is a non-contact spraying method that does not cause mechanical damage to the proton exchange membrane, and can avoid problems such as membrane rupture and deformation caused by the spraying process, effectively protecting the structural integrity of the proton exchange membrane.

- Suitable for various coatings: whether it is carbon based catalyst ink, precious metal catalyst solution, or other functional coatings, ultrasonic spraying equipment can adapt well, providing more choices for the functionalization of proton exchange membranes.

About Cheersonic

Cheersonic is the leading developer and manufacturer of ultrasonic coating systems for applying precise, thin film coatings to protect, strengthen or smooth surfaces on parts and components for the microelectronics/electronics, alternative energy, medical and industrial markets, including specialized glass applications in construction and automotive.

Our coating solutions are environmentally-friendly, efficient and highly reliable, and enable dramatic reductions in overspray, savings in raw material, water and energy usage and provide improved process repeatability, transfer efficiency, high uniformity and reduced emissions.

Chinese Website: Cheersonic Provides Professional Coating Solutions