Ultrasonic Fuel Cell Coating System

In order to meet the needs of improving the efficiency and reducing the cost of fuel cells, we use ultrasonic spraying to uniformly coat a thin layer during the manufacturing process. We have developed an automated method for the precise application of fuel cell coating materials. Ultrasonic nozzles and sophisticated liquid handling and delivery systems are a major improvement over traditional application technologies.

Ultrasonic Fuel Cell Coating System Video

Ultrasonic Nozzle Spraying Fuel Cell Catalyst Ink:

• Increased platinum utilization to 90% in MEA manufacturing.

• The highly porous coating is highly durable and prevents cracking or peeling of the catalyst layer.

• Reduced material consumption by more than 50%, reducing overspray means saving expensive catalyst inks.

• Clean, precise spray, easy to shape to suit a variety of applications.

• Highly controllable spray is easy to prepare with high uniformity and good uniformity.

• High frequency vibration makes the nozzles less likely to be blocked.

• Ultra-low flow capacity, intermittent or continuous.

• Ultrasonic vibration continuously breaks up agglomerated particles and evenly disperses them; maximizes the use of platinum.

• Coating PEM with very small liquid sample sizes (only 10 ml of catalyst solution is required to coat multiple PEMs). Ideal for R & D.

• Best for high vibration fuel cell applications, such as automotive parts.

Recommended Equipment

Ultrasonic Atomization Nozzle

Laboratory Ultrasonic Coating System

Desktop Ultrasonic Spraying Machine

Desktop Ultrasonic Precision Spraying Machine

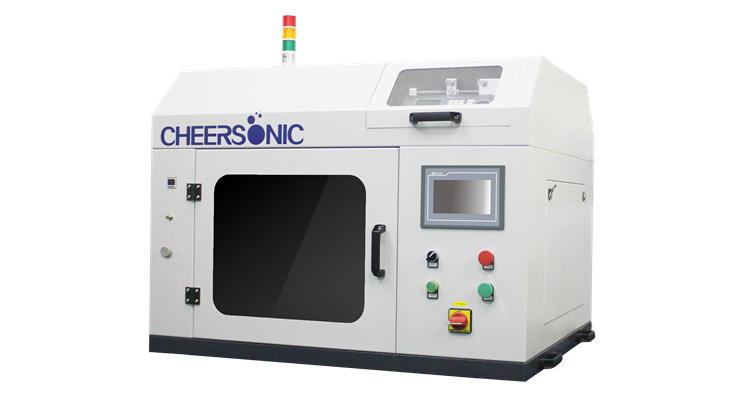

Medium Ultrasonic Spraying Machine

Ultrasonic Stent Coating System

Ultrasonic Balloon Coating Equipment

Inline Ultrasonic Coating System

UAL100 Ultrasonic Dispersion Syringe Pump

LULP500 Ultrasonic Laboratory Device

Prosonic1000 Industrial Ultrasonic Device

Prosonic3000 Most Powerful Ultrasonic Processor