Ultrasonic Flux Spraying on PCB

Ultrasonic Flux Spraying on PCB – Ultrasonic Nozzle – Cheersonic

Ultrasonic spraying machines have shown significant advantages in the spraying of water-soluble flux on PCBs (printed circuit boards), mainly reflected in the following aspects:

1、 Spray uniformity

Ultrasonic spraying machine uses ultrasonic vibration to break liquid flux into tiny droplets, and uniformly sprays them on the surface of PCB through high-frequency vibration. This technology does not rely on external airflow to form atomization effects, so it can better control the spraying flow rate, speed, and direction, thereby achieving uniform spraying effects. Compared to traditional two fluid or air pressure spraying methods, ultrasonic spraying can significantly improve the uniformity of spraying, achieving ideal results on both flat and curved surfaces, large and small areas.

2、 Save raw materials and promote environmental protection

Due to the fact that the ultrasonic spraying method only requires a small amount of carrier gas to assist in forming a stable droplet flow, it can greatly reduce the loss of raw materials and improve the utilization rate of raw materials. According to statistics, compared to traditional spraying methods, ultrasonic spraying can save more than 40% of raw materials. In addition, due to the reduction of solvent and active substance emissions, ultrasonic spraying method can significantly reduce the emission of VOCs (volatile organic compounds), thereby reducing environmental pollution. This is undoubtedly an important advantage for the electronics industry, which has increasingly strict environmental requirements.

3、 High precision and high efficiency

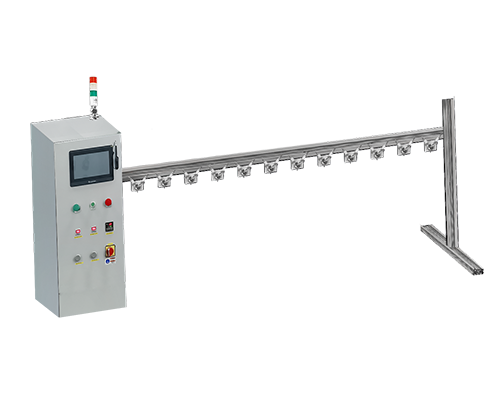

Ultrasonic spraying equipment can accurately control the frequency, power, and phase of ultrasonic waves, as well as the shape, size, and angle of the nozzle, thereby achieving precise control of spraying flow rate, speed, and direction. This high-precision control can reduce waste and unevenness during the spraying process, and improve spraying efficiency. At the same time, ultrasonic spraying machines have fast spraying speed, simple operation, and can achieve automated production, further improving production efficiency.

4、 Improve welding quality

In the soldering process of PCB, the main function of flux is to remove oxides on the metal surface, improve the wettability between the metal and solder, and thus promote the soldering process. Ultrasonic spraying technology can evenly spray flux on the welding surface, enabling the flux to better function and improve the quality and reliability of welding. In addition, due to the uniformity and high precision of ultrasonic spraying, it can also reduce defects and defect rates during the welding process.

5、 Strong adaptability

Ultrasonic spraying equipment can use various types and properties of liquids as raw materials, including water-based or oil-based fluxes, low viscosity or high viscosity fluxes, etc. Therefore, it can adapt to the spraying requirements of different types and needs of PCBs. The strong adaptability of ultrasonic spraying technology makes it widely applicable in the electronics industry.

In summary, ultrasonic spraying machines have significant advantages in water-soluble flux spraying on PCBs, including high spraying uniformity, saving raw materials and environmental protection, high precision and efficiency, improving welding quality, and strong adaptability. These advantages have led to the widespread application and recognition of ultrasonic spraying technology in the electronics industry.

About Cheersonic

Cheersonic is the leading developer and manufacturer of ultrasonic coating systems for applying precise, thin film coatings to protect, strengthen or smooth surfaces on parts and components for the microelectronics/electronics, alternative energy, medical and industrial markets, including specialized glass applications in construction and automotive.

Our coating solutions are environmentally-friendly, efficient and highly reliable, and enable dramatic reductions in overspray, savings in raw material, water and energy usage and provide improved process repeatability, transfer efficiency, high uniformity and reduced emissions.

Chinese Website: Cheersonic Provides Professional Coating Solutions