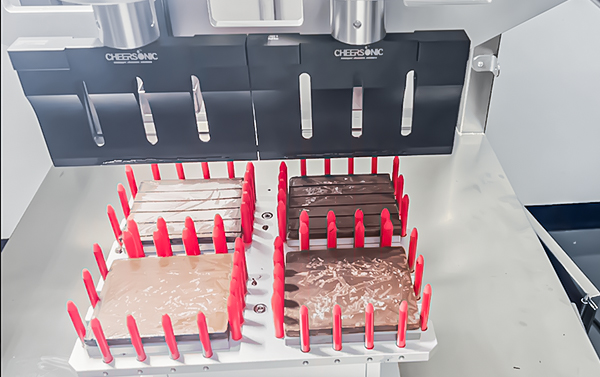

Ultrasonic Cutting Machine for Cutting Chocolate Bars

Precise and delicate: innovative application of ultrasonic cutting technology in chocolate processing

In the field of chocolate making, which pursues ultimate taste and exquisite appearance, every technological innovation leads the progress of the industry. In recent years, ultrasonic cutting technology has demonstrated extraordinary innovative applications in chocolate processing with its unique precision and delicacy, bringing unprecedented processing experience and product upgrades to chocolate manufacturers.

The biggest advantage of ultrasonic cutting technology is its extremely high cutting accuracy. In chocolate processing, whether it is the need to create intricate patterns, complex shapes, or require smooth and flawless cutting edges, ultrasonic cutting can easily handle them. This precision not only enhances the appearance quality of chocolate, but also ensures the integrity of its internal structure, avoiding taste loss caused by improper cutting.

In addition to precision and delicacy, ultrasonic cutting technology is also known for its high efficiency. Compared to traditional cutting methods, ultrasonic cutting can complete cutting tasks faster and does not require frequent tool changes or parameter adjustments during the cutting process, greatly improving production efficiency. Meanwhile, due to high cutting accuracy and low scrap rate, it indirectly reduces production costs. This is undoubtedly a huge advantage for chocolate manufacturers.

In today’s increasingly environmentally conscious society, the environmental and energy-saving characteristics of ultrasonic cutting technology have also attracted much attention. This technology does not require the use of additional coolant or lubricants, reducing chemical emissions and environmental pollution. Meanwhile, due to the minimal heat generated during the cutting process, it also reduces energy consumption and carbon emissions. This is in line with modern industry’s pursuit of green and sustainable development.

The innovative application of ultrasonic cutting technology in chocolate processing not only improves the quality and taste of products, but also enhances production efficiency and environmental performance. With the continuous development and improvement of technology, we believe that ultrasonic cutting will play a more important role in the future chocolate processing field, bringing more delicious and surprising experiences to consumers.

About Cheersonic

Cheersonic manufactures the leading portioning equipment for bakeries producing fresh and frozen desserts. Since 1998 bakers have used Cheersonic machines to cut, slice and portion cheesecake, pie, layer cake, loaves, butter, cheese, pizza, sandwichs, and more. Cheersonic offers ultrasonic cutting solutions that support start-up bakeries and high production commercial facilities alike. Small standalone machines can be used in manual baking facilities and large inline robotic solutions aid in high speed production.

Cheersonic offers many ultrasonic slicing models, both inline and offline applications, with production speeds of 80 to 1,500 cakes or pies per hour.

Cheersonic’ latest offline introductions include ultrasonic cutting with or without divider inserts between each slice. This improves the quality of the cut and makes for a much better product presentation for the customer. In addition, robotic arm improves the speed, efficiency, and accuracy of the cutting process, producing professional looking products every time.

Chinese Website: Cheersonic Provides Professional Ultrasonic Cutting Solutions