Ultrasonic Coating Machine for Electrolyzer Coatings

Ultrasonic spraying machines have shown significant advantages and broad application prospects in spraying electrolytic cells. The following is a detailed analysis of the ultrasonic spraying machine spray electrolyzer:

1. Overview of ultrasonic spraying technology

Ultrasonic spraying technology is achieved through ultrasonic atomization technology, which uses ultrasonic energy to disperse water or liquid to form particles ranging from a few microns to 100 microns in size, thereby achieving spraying. This technology enables precise control of droplet size, liquid flow rate and spray pattern to ensure a uniform and efficient coating.

2. Application of Ultrasonic Coating Machine for Electrolyzer Coatings

PEM electrolyzer spraying

- Application background: PEM (proton exchange membrane) electrolyzer is one of the most critical components in fuel cells, and its performance directly affects the production efficiency and quality of hydrogen. PEM electrolyzers need to operate in strong acid and highly oxidizing working environments, so the requirements for coating materials are extremely high.

- Advantages: Ultrasonic spray technology can provide uniform and efficient thin film spraying to ensure consistent coating thickness and no defects, thereby improving the corrosion resistance and conductive performance of the electrolytic cell. In addition, this technology can also reduce painting costs, improve production efficiency, and reduce environmental pollution.

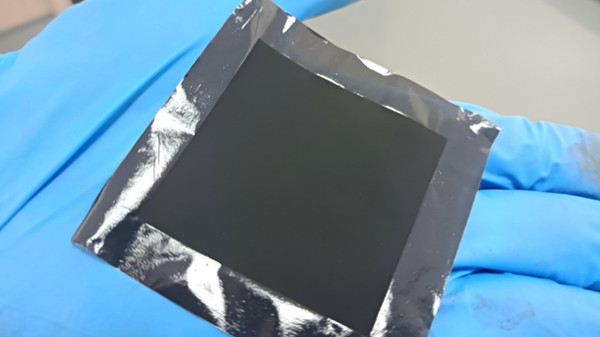

- Specific application: Spray coating materials with corrosion resistance and excellent conductivity on the cathode and anode plates, diaphragms and other components of the PEM electrolyzer to improve the overall performance and service life of the electrolyzer.

AEM Electrolyzer Spraying

- Application background: AEM (anion exchange membrane) electrolyzer is another key technology for hydrogen energy production, and its performance is also affected by the coating material.

- Advantages: The application of ultrasonic spraying technology in the field of AEM electrolytic cell preparation can achieve precise and uniform spraying of coating materials, ensuring consistent coating thickness and no defects. This helps improve the corrosion resistance and conductivity of the electrolyzer, extending its service life. At the same time, this technology can also improve electrolysis efficiency and hydrogen purity, and reduce production costs.

- Specific application: Spray catalyst material on the electrode surface of the AEM electrolyzer to form a uniform and dense catalyst coating; coat conductive materials on the electrolyte channel to improve the conductive performance of the electrolyzer.

3. Advantages of ultrasonic spraying machine for spraying electrolytic cells

Improve coating uniformity and adhesion: The paint droplets formed by ultrasonic spraying are more uniform, which can significantly improve the surface flatness and adhesion of the coating.

Reduce painting costs: Compared with traditional painting methods, ultrasonic spraying technology can reduce labor operation costs and improve painting efficiency.

Improve the surface accuracy and smoothness of the workpiece: Due to the tiny paint particles, ultrasonic spraying can achieve finer surface accuracy and smoothness.

Improve the corrosion resistance and wear resistance of the coating: The coating formed by the ultrasonic spraying process has a denser microstructure and higher bonding force, so it has better corrosion resistance and wear resistance.

4. Conclusion

In summary, ultrasonic spraying machines have significant advantages and broad application prospects in spraying electrolytic cells. With the continuous advancement of technology and reduction of costs, it is believed that ultrasonic spray technology will play a greater role in the field of hydrogen energy preparation and promote the rapid development of the hydrogen energy industry.

About Cheersonic

Cheersonic is the leading developer and manufacturer of ultrasonic coating systems for applying precise, thin film coatings to protect, strengthen or smooth surfaces on parts and components for the microelectronics/electronics, alternative energy, medical and industrial markets, including specialized glass applications in construction and automotive.

Our coating solutions are environmentally-friendly, efficient and highly reliable, and enable dramatic reductions in overspray, savings in raw material, water and energy usage and provide improved process repeatability, transfer efficiency, high uniformity and reduced emissions.

Chinese Website: Cheersonic Provides Professional Coating Solutions