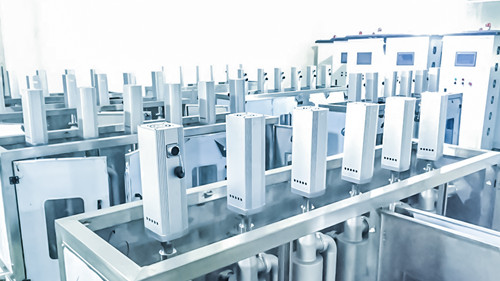

Ultrasonic Battery Slurry Dispersion

The preparation of lithium battery slurry includes a series of processes such as mutual mixing, dissolution and dispersion between liquid and liquid, liquid and solid materials, and the process is accompanied by changes in temperature, viscosity, and environment. The mixing and dispersion of lithium battery slurry always accompanies the whole process of lithium battery slurry preparation.

Ultrasonic battery slurry dispersion and lithium battery slurry dispersion produce stirring due to the instantaneous acoustic cavitation effect of ultrasonic waves. Ultrasonic stirring can achieve the same effect as stirring based on hydrodynamic technology. Ultrasonic agitation of ultrasonic technology is particularly advantageous for battery slurry preparation.

By utilizing ultrasonic technology, ultrasonic lithium battery slurry dispersion can not only reduce battery production cost, but also improve battery capacity and cycle stability.

Performance Characteristics

1. Typical applications include homogenization, emulsification, dispersion, deagglomeration and wet milling (particle size reduction), cell disruption and disintegration, extraction, degassing, and sonochemical processes

2. The newly designed display screen can easily observe the actual working frequency and adjust the power/amplitude

3. Automatic frequency tracking to ensure that it is always in the best working condition

4. Automatic matching and tracking to ensure that the frequency (power) is in the best working condition