Ultrasonic Atomizer For Catalysts

The electrocatalytic activity of Pt/C catalysts is influenced by many factors, such as average particle size, relative crystallinity, surface groups, surface morphology, and the Pt–C interface. Therefore, when Pt/C catalysts are prepared using different methods or different carbon supports, many factors can influence their electrocatalytic activity, leading to different conclusions.

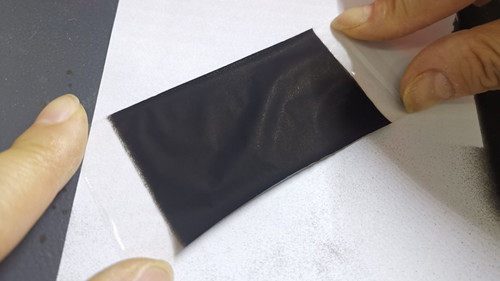

Ultrasonic nozzles produce a soft, low velocity spray resulting in a minimum of overspray. When low velocity gas is used to shape the spray plumes of ultrasonic atomizers, the highest transfer efficiencies of expensive materials are possible.

Specifically, the following are inherent conditions:

1. Very high Platinum utilization proven in MEA fabrication; as high as 90%.

2. Highly porous coatings are extremely durable, preventing cracking or peeling of catalyst layer.

3. Capable of coating PEMs with very small liquid sample sizes (only 10ml of catalyst solution necessary to coat multiple PEMs). Ideal for R&D phase.

Fuel Cell Catalyst Coating Systems Video

Recommended Equipment

Ultrasonic Atomization Nozzle

Laboratory Ultrasonic Coating System

UAM3000 Ultrasonic Medical Devices Spraying

UAM4000 Desktop Ultrasonic Spraying Equipment

UAM4000L Benchtop Ultrasonic Spray System

UAM6000 Ultrasonic Spraying Machine

UAL100 Ultrasonic Dispersion Syringe Pump

LULP500 Ultrasonic Laboratory Device

Prosonic1000 Industrial Ultrasonic Device

Prosonic3000 Most Powerful Ultrasonic Processor