Ultrasonic Atomized Spray Glass Application

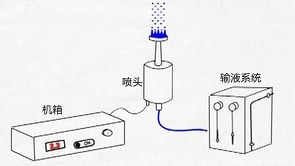

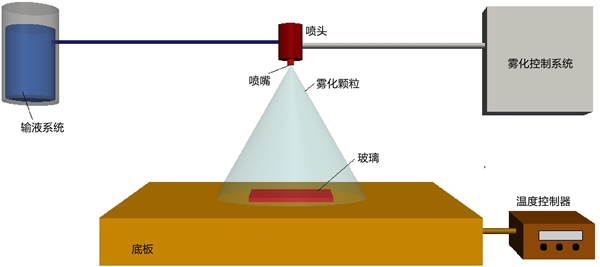

The principle of ultrasonic atomization spraying:

When the ultrasonic electric box converts the commercial power into high-frequency electric energy, the high-frequency electric energy is converted into vibration mechanical energy when it reaches the transducer. Mechanical energy breaks up the liquid into um-level mist particles.

Advantages: 1. Reduce waste 2. Relatively environmentally friendly 3. Evenly atomized 4. Thin coating

Application of ultrasonic atomizing spray on glass:

1.TCO conductive glass. TCO glass (transparent conductive oxide coated glass) was uniformly plated with a transparent conductive oxide film on a flat glass by spray pyrolysis. Mainly used in the field of solar cells, and OLED screens.

2.AR anti-reflective glass is coated with an anti-reflection film on the surface of ordinary tempered glass to effectively reduce the reflection of the glass itself and increase the transmittance. Such as solar tubes, computer screens, etc.

3.AF anti-fingerprint oleophobic glass is coated with a layer of chemical material on the outer surface of the glass to minimize the surface tension of the glass and reduce the contact area between the dust and the glass surface by 90%. Such as mobile phone screens, tablets, and so on.

Ultrasonic Spray Video

Recommended Equipment

Ultrasonic Atomization Nozzle

Laboratory Ultrasonic Coating System

UAM3000 Ultrasonic Medical Devices Spraying

UAM4000 Desktop Ultrasonic Spraying Equipment

UAM4000L Benchtop Ultrasonic Spray System

UAM6000 Ultrasonic Spraying Machine

UAL100 Ultrasonic Dispersion Syringe Pump

LULP500 Ultrasonic Laboratory Device

Prosonic1000 Industrial Ultrasonic Device

Prosonic3000 Most Powerful Ultrasonic Processor