Ultrasonic Atomization Of Fuel Cell

Cheersonic ultrasonic nozzles are effective in both the manufacture of fuel reforming system components and the ultrasonic atomization of fuel during reforming.

Applications:

• Ultrasonic atomize hydrocarbon fuels (such as methanol and diesel) into a steam reformer to mix fuel and hot air / steam quickly and thoroughly at low flow rates.

• Spray catalyst suspensions (such as alumina suspensions) onto membranes or conductive solid oxide fuel cells in the reformer.

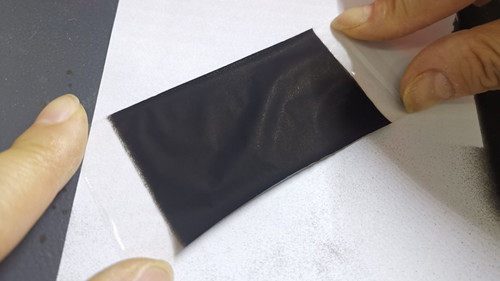

• Spray a polymer solution onto a porous substrate to form an electrolyte membrane for fuel cells or a membrane for separating H2 from syngas.

• Various catalyst coatings on open-cell filter assemblies (including aluminum screens, ceramic honeycombs, or stainless steel foam) to maintain porosity without blocking micropores.

Ultrasonic nozzles provide many benefits during fuel reforming:

• Deagglomeration of particles in suspension.

• Uniform film.

• Controllable drop size.

• Ability to uniformly coat complex filter geometries, which improves the surface area of the active catalyst.

• Spray as little expensive catalyst material as possible.

• Better control of the repair base coating process, uniform deposition and control of coating thickness.

Ultrasonic Atomization Of Fuel Cell Video

Recommended Equipment

Ultrasonic Atomization Nozzle

Laboratory Ultrasonic Coating System

UAM3000 Ultrasonic Medical Devices Spraying

UAM4000 Desktop Ultrasonic Spraying Equipment

UAM4000L Benchtop Ultrasonic Spray System

UAM6000 Ultrasonic Spraying Machine

UAL100 Ultrasonic Dispersion Syringe Pump

LULP500 Ultrasonic Laboratory Device

Prosonic1000 Industrial Ultrasonic Device

Prosonic3000 Most Powerful Ultrasonic Processor