Titanium Bipolar Plate

As the core component of PEMFC, bipolar plate has a very important role in battery output power, cost control and service life. The ideal bipolar plate has the characteristics of low price, light weight, excellent corrosion resistance and good electrical and thermal conductivity. Metal is an ideal PEMFC titanium bipolar plate material, and is considered to be the development direction of PEMFC industrialization.

The metal bipolar plate has the characteristics of high strength, good ductility, mature processing technology, good electrical and thermal conductivity, etc., which can effectively reduce the thickness and quality of the battery stack, greatly improve the energy density of PEMFC, and become the current PEMFC bipolar plate research. The focus of attention.

In addition, the low density and high strength of titanium and titanium alloys in metal materials have good corrosion resistance in PEMFC, and the corrosion products generated during service are less toxic to proton exchange membranes and catalysts, which can ensure the operational stability of PEMFC And the long service life has become the mainstream material for the current research of metal bipolar plates.

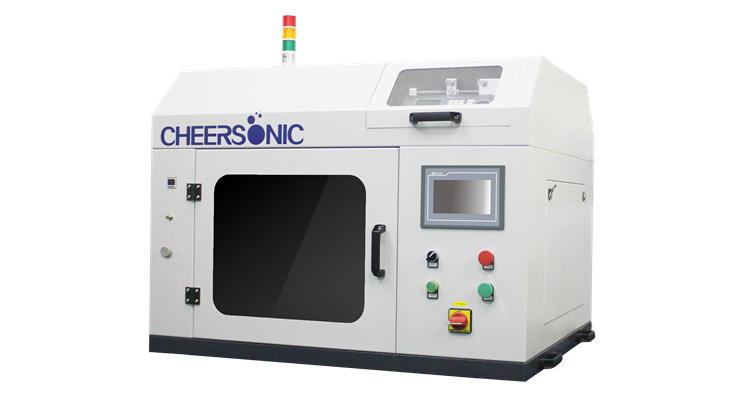

At present, the surface modification methods of Ti metal bipolar plates mainly include electroplating and electroless plating, physical vapor deposition technology (PVD), chemical vapor deposition (CVD), ultrasonic spraying method, hydrothermal method, etc.