Test Laboratory

Cheersonic will move to a new factory in November 2020 to build a new higher-level laboratory. The new test laboratory will enable customers to test their sample liquids in a controlled environment, simulating process conditions as much as possible to prove the concept and ensure liquid compatibility. For emerging applications, such as advanced energy coatings and special medical device coatings, higher-level laboratories can better realize the value of testing.

Research and development professionals who are looking for a new coating formulation or improving the properties of functional coatings can come to our company’s testing facilities. This is an excellent way to find the correct solution to their coating problems. Over the years, Cheersonic has provided laboratory testing services to ensure that each customer’s final machine meets their actual production requirements and gives me ideal spray settings.

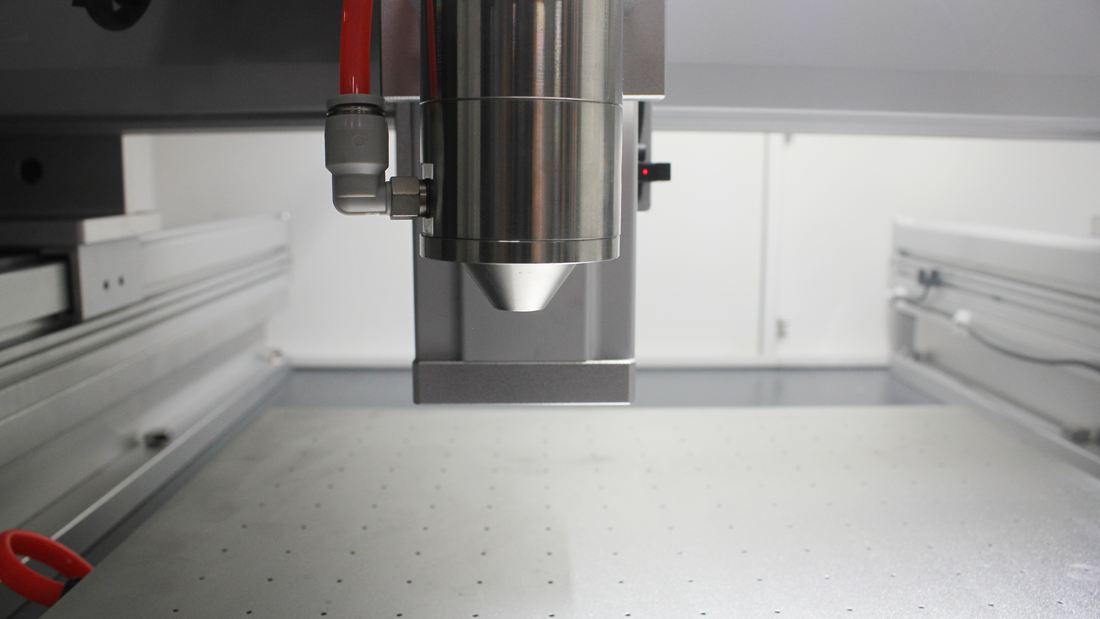

Cheersonic’s laboratory equipment includes a fully enclosed 3-axis programmable coating system with multiple fixtures, heating and vacuum options, and a variety of different nozzle configurations. In addition, it is equipped with microscope, dryer, ventilation equipment, film thickness gauge and so on.