Spraying Photo Resistive Coatings

Photoresist coatings are used for both electronic device and microelectromechanical (MEMs) device production. Photoresists are typically polymeric materials that are either enhanced (i.e. via cross-linking, negative photoresist materials) or solubilized (positive photoresist materials) via exposure to light, hence light is used to pattern photoresist coatings on substrates, a technique known as photolithography. Resist-coated substrates are then exposed to particular solvent(s) or solution(s), known as developers, to remove unwanted resist material, often in preparation for etching and/or the application of other functional material(s) to a substrate.

Cheersonic nozzles can be utilized to clean substrates, as well as provide gentle, uniform coatings of resist material(s) to a controllable thickness. Cheersonic nozzles can also be utilized to spray solvents or solutions used to remove unwanted resist material, etch substrates, and potentially even add other desired materials to these devices. Cheersonic can produce or assist in developing automated coating systems to move substrates through some or all of these steps, of benefit for design, prototyping, and/or scaling of production of MEMs or other electronic devices.

Recommended Machine

UAL100 ultrasonic dispersion liquid supply system

UAM3000 Ultrasonic Bracket Spraying Machine

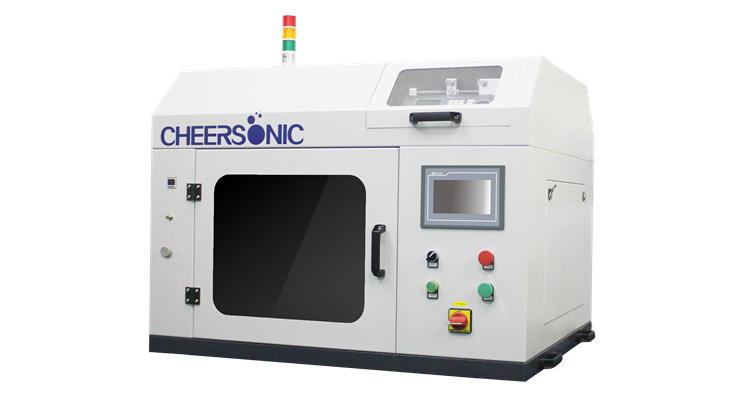

UAM4000 small desktop ultrasonic spraying machine

UAM4000L Ultrasonic Precision Spraying Machine

UAM6000 Ultrasonic Large Spraying Machine

UAM7000 Ultrasonic Balloon Guide Wire Spraying Machine

UAM8000 ultrasonic assembly line spraying machine