Spraying Fuel Cell Coating

Cheersonic nozzles can also be used to coat electrode or membrane substrates with catalyst materials. As a consequence of synthesis, or post-synthesis, depending on the technique used, catalyst particles are often suspended, forming “inks”, which then need to be coated onto appropriate electrodes or membranes for use in fuel cells.

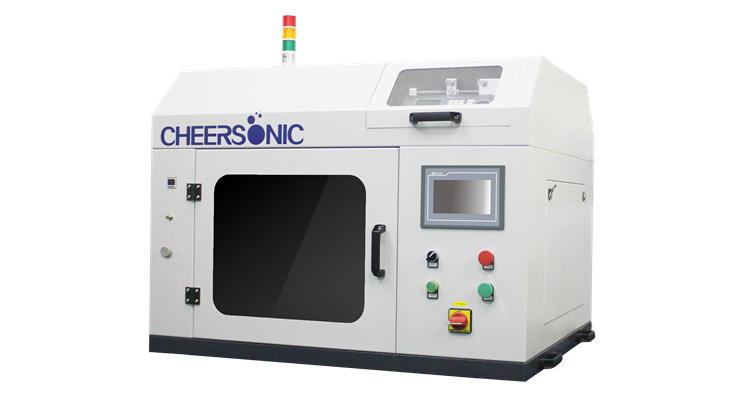

Cheersonic’s ultrasonic spraying fuel cell coating and automated robotic coating systems can be used to accurately, precisely, and uniformly coat catalyst films and layers onto such substrates, minimizing overspray and hence minimizing waste, which is also important for device optimization, reproducibility, sustainability, and cost savings.

Cheersonic develops ultrasonic coating systems from the benchtop/research level up, allowing for scalability of processes used to create novel, “cutting-edge” fuel cell catalysts as part of a clean, sustainable energy future. Furthermore, solution- or suspension-based spraying using Cheersonic nozzles can potentially be utilized to print or coat solid oxide fuel cell materials, even if such spraying need occur over a heated substrate or in a heated environment such as an oven or furnace.