Proton Exchange Membrane Coating System

Performance and Durability of Electrodes with Platinum Catalysts in Polymer Electrolyte Cells Prepared by Ultrasonic Spray Deposition

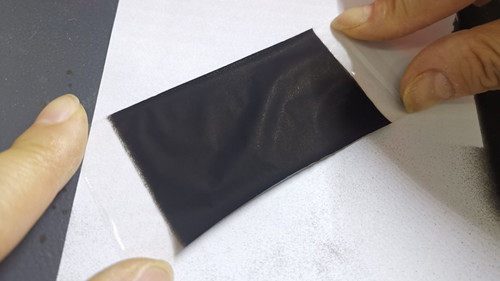

Proton exchange membrane (PEM) fuel cell system. The power generation element of a fuel cell system is a membrane electrode assembly (MEA). A method of preparing a MEA for a polymer electrolyte fuel cell using a direct ultrasonic spray deposition method using a platinum black catalyst suspension was developed. A 50 kHz ultrasonic head is used to coat a thin, uniform electrode layer on a substrate. These electrodes are designed to operate at high efficiency when operating under pressurized H2 and O2 to meet the fuel cell system’s efficiency goals, namely a current density of 200 mA / cm2 and a potential> 900 mV. For electrode deposition, the catalyst is suspended in a mixture of water and isopropanol solvent and the ink formulation is optimized. Through this method of direct deposition onto polymers, the conductivity between ion channels can be improved. As a result, the electrode preparation method brings benefits in battery performance compared with the conventional method.

Proton Exchange Membrane Coating Spray Video

Recommended Equipment

Ultrasonic Atomization Nozzle

Laboratory Ultrasonic Coating System

UAM3000 Ultrasonic Medical Devices Spraying

UAM4000 Desktop Ultrasonic Spraying Equipment

UAM4000L Benchtop Ultrasonic Spray System

UAM6000 Ultrasonic Spraying Machine

UAL100 Ultrasonic Dispersion Syringe Pump

LULP500 Ultrasonic Laboratory Device

Prosonic1000 Industrial Ultrasonic Device

Prosonic3000 Most Powerful Ultrasonic Processor