Project Description

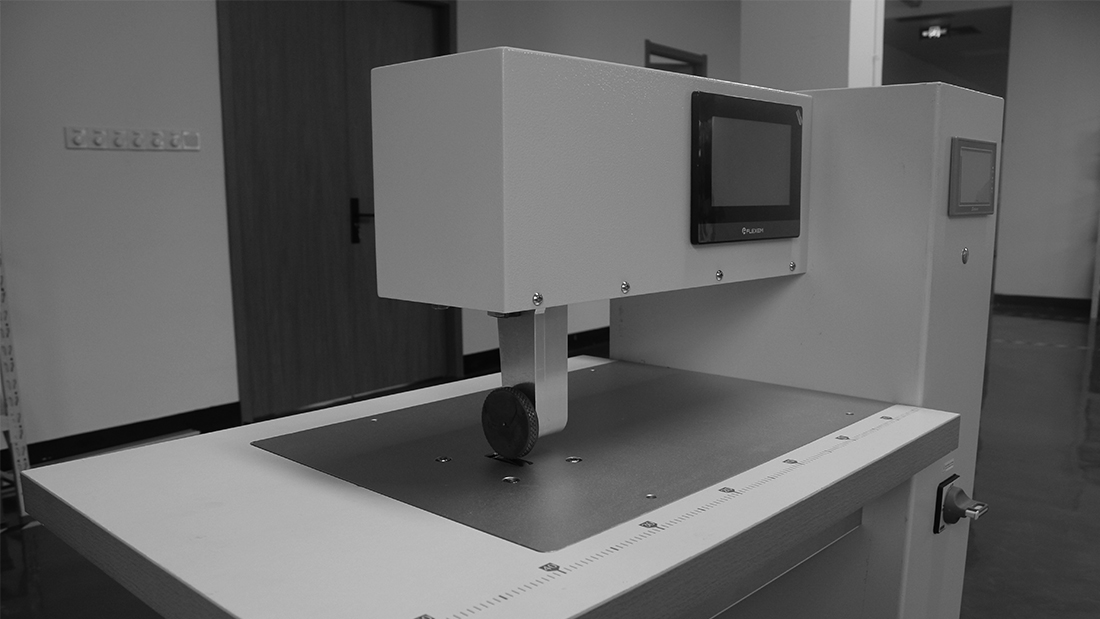

UWM550WL Ultrasonic Sewing Machine

Principle

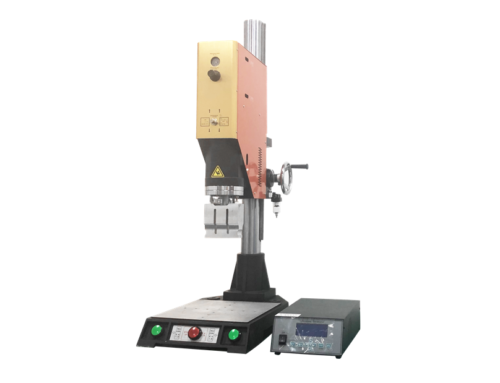

A modern ultrasonic welding machine is a flexible all-rounder that is easy to use and an effectiv way to produce high quality results . The new generation of the UWM550WL makes efficient and precise work possible. Through the use of high-tech components our UWM550WL guarantees a high quality of processing.

When welding continuously by the ultrasonic method, the material to be welded will be subjected to rapid changing pressure vibrations.

The heat develops because of molecular vibrations beneath the material surface, for thin materials within the immediate vicinity of the actual weld.

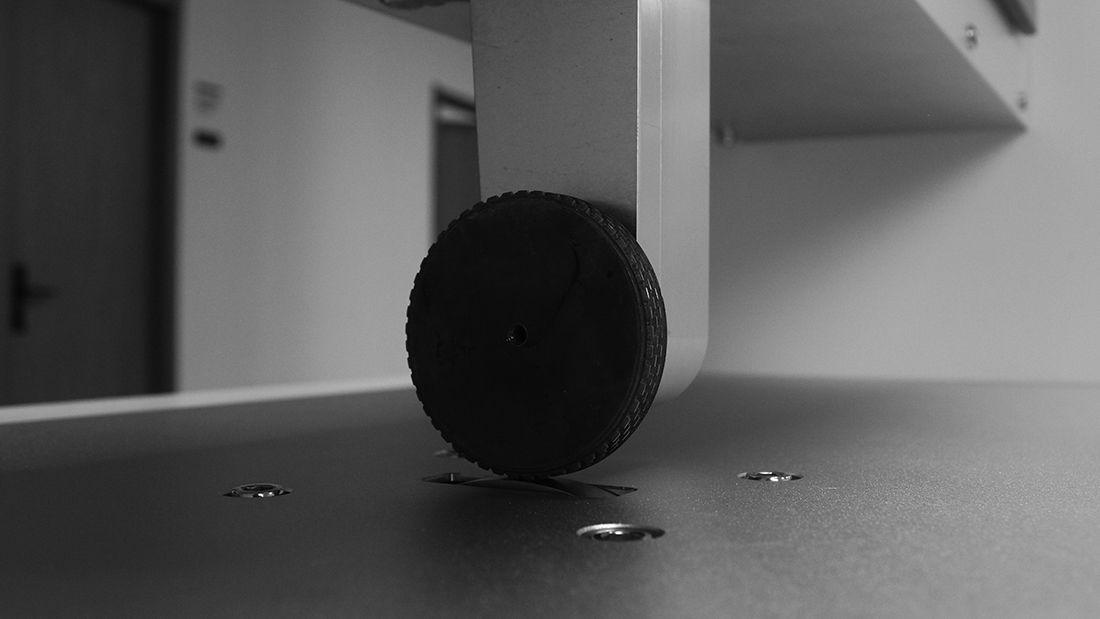

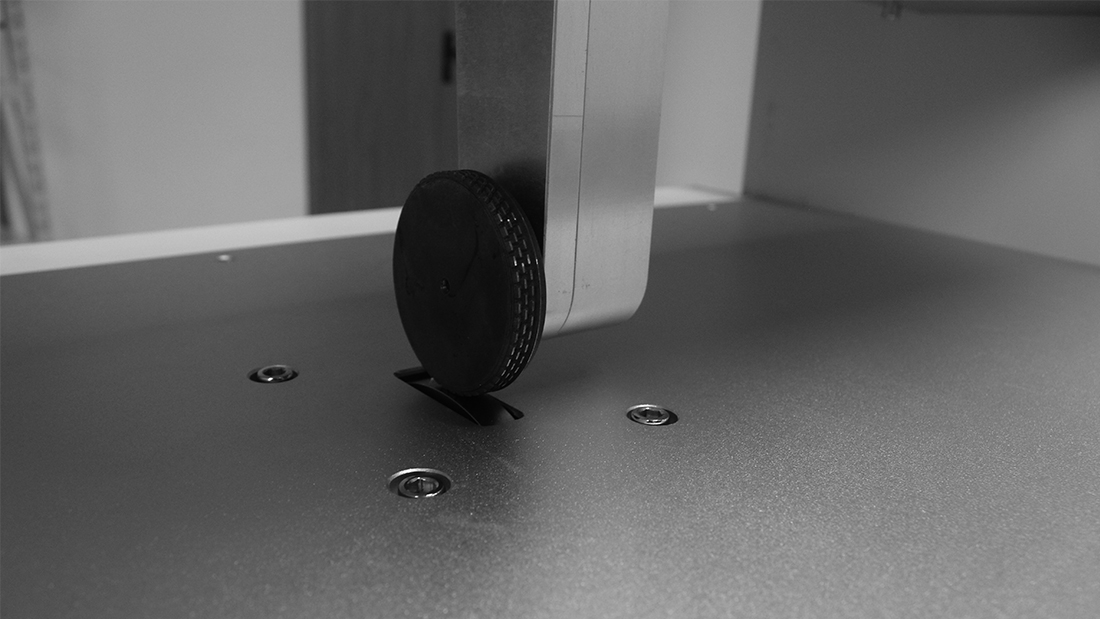

This solution features two anvil wheels (one for cuting and sealing and the other one to realize the second weld seam) on one post, but on separate shafts. With this solution the load may be individually adjusted – the wo wheels are still running in sync. The minimum distance between weld seam an cutting is around 1 mm.

Features

• Long arm version 1000 mm

• Seams, trims, and seals without thread, glue, or other consumables

• Seam distances resp. operating cycles can be programmed (sequence welding)

• Reproduibility of the welding process. Runs problem-free in continuous operation.

• More efficient than sewing, heat sealing, adhesive machines, or stationary sonic operations

• Performs faster than conventional sewing machines and adhesive methods

• Virtually eliminates fraying or unraveling of bonded edges and seams

• Available in a variety of easy-to-change slit pattern wheels

• Requires only minimal operator training

• Equipped with differential feed; separate drive for sonotrode and anvil wheel: that means smooth, non-distorted seams or the possibility of adding a some fllness

• Process reliability through monitoring of welding parameters with integrated device for constant performance (so that reliable processing is possible even when sewing over cross seams)

Applictions

• Industrial safety: protective suits, sun protection, parachutes, operations sheets, foils, bullet proof vests, blinds and awnings, pleated filter, shower curtains, spacer fabrics, seat covers, MBR -modules.

• Fashion/Sportswear: sportswear, jackets, swimwear, hot air balloon, outdoor garment, Tyvek protective clothing, bras, lingerie, softshell a, sport garments, clean-room garments and so on

• Filtration: pleated filters, filter bags, (multi) pocket filters, star filter

• Automotive: airbag, vehicle interior and insulation item, protective car covers, sunshades

• Hygiene Medical: medical garment & drapes, medical apparel, surgical cloths, medical layers, mask, health care articles, medical mattresses and pillows, needle felts, surgical drapes, surgical overlays and surgical clothing, as well as hygiene articles such as mouth guards, diapers or bandages and compression articles can be individually welded.

| Model | UWM550WL Ultrasonic Sewing Machines |

| Sealing speed | 0.5 to 10 m/min. option to 20m/min |

| Seam width | 1,0 to 10,0 mm |

| Connection voltage | single-phase a.c. 230 V, 50/60 Hz |

| Tuning | Automatic |

| Weight | 200kg |

| Frequency | 35khz |

| Compressed Air | Clean, dry air at 90psi (6.3Kg/cm2), 2 CFM (1 liter per sec) |

| Whether Customization | YES |

| Output Power | 600watt |