Project Description

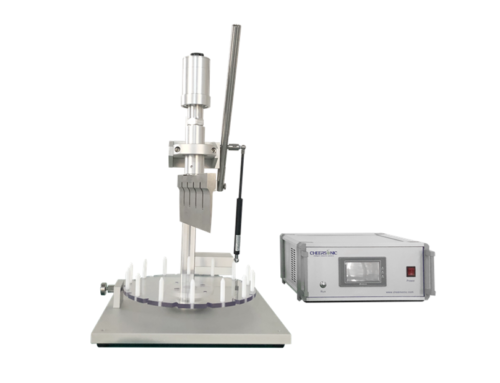

UFM3500B Ultrasonic Swiss Roll Slicing Equipment

Product Description

UFM3500B Ultrasonic Swiss Roll Slicing Equipment is an inline food slicing machine with ultrasonic cutting technology, built to process sticky, frozen, delicate and complex products, such as sponge cakes, cheesecakes, brownie cakes, pies, quiches, pizza, pastries and other bar- shaped products with a wide rang of temperature from -15 degree Celsius to ambient temperature. And it allows each slice to have a clean quality cutting surface. It could be used not only as a stand alone solution, but also be integrated into existing production lines. Ultrasonic Swiss Roll Slicer is suitable for the manufactures with medium and high output and much space.

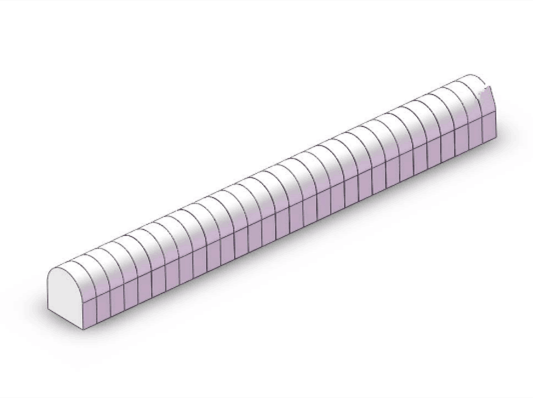

Cutting Mode Schematic

Actual Cutting Effect Image

Advantage

• Average speed: about 150-600 pieces per hour

• Color touch screen with User friendly interface

• Reliable and durable ultrasonic machine

• Increased quality and labor saving enhance capacity

• Improved portion quality and consistency

Key Features

• Fully Stainless steel construction & food grade plastics

• Easy to clean the blade and machine

• A wide range of blade types for various applications

• Slicing bar-shaped, loaf products

• A function of sterilization with UV light

• Remote access capability with Ethernet

• Safety protective door

• Motor-driven rotary ultrasonic blade

• Easy-to-use editing programs

• 3 user login levels-operator, supervisor and technician

| UFM3500B Ultrasonic Swiss Roll Slicing Equipment | |

| Dimensions (length) x (width) x (high) | 2415*650*1800 |

| Weight | 350Kg |

| Rated power | 3.5kw |

| Cutting speed | 60 knives / min |

| Maximum cutting size | Up to 500 mm in width |

| Maximum effective cutting height | 60mm (80mm optional) |

| Number of cutting knives | 2 |

| Cutting knife size | 255mm (305mm optional) |

| Whether it can be rotated | No |

| Cut type | Sliced |

| Conveyor belt (several) | Yes (One belt) |

| Rack structure | Stainless steel |

| Safety protection system | Safety protection door |

| Screen | 7 inch touch screen |

| Control cabinet | Built-in |

| Control System | Multi-axis Control System |

| Cutting knife control system | Servo motor |

| Electric supply | Single phase, 220v, 50-60Hz |

| Compressed air connection | Max. 0.4Mpa |

| Product into and out of material | Automatically or manually |

| Machine mobility | Pully |