Project Description

Ultrasonic Substrate Coating

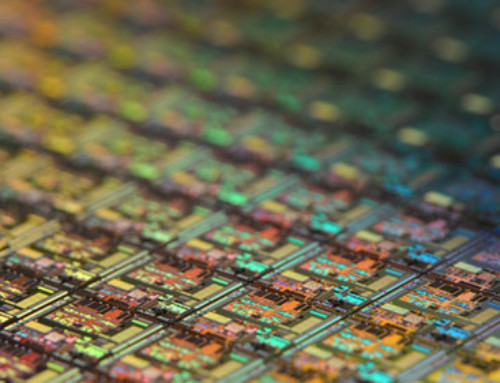

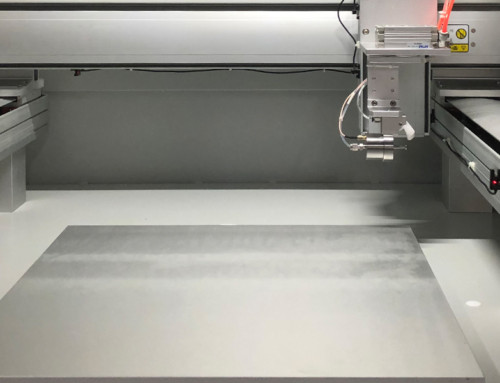

Ultrasonic nozzles can be used to coat a variety of substrates, including various liquids, solutions, suspensions, emulsions, etc., for a variety of applications. The CHEERSONIC Ultrasonic Coating System delivers accurate, accurate and repeatable substrate coatings in a single, batch or continuous process setup. Our nozzles allow for graded coatings or bond coats, and even individual nozzles for multilayer coatings, which may be particularly suitable for fuel cell applications in photovoltaic or solid oxides. This automated system is also suitable for medical diagnostics and testing of substrates or other coatings of biomedical interest, for example for medical stents, catheters or biomedical implants.

The ultrasonic atomizer sprays droplets of uniform particle size onto the surface of the substrate to form a uniform coating. The liquid passes through the center hole of the nozzle and is atomized at the tip of the nozzle, and the gas surrounds the water droplets. The nozzles are intermittently sprayed at low speeds with virtually no overspray, making them ideal for spraying precision films with nano or micro thicknesses.

Ultrasonic Coating Video