Project Description

Ultrasonic Spray Pyrolysis of Thin Films

Surfactant-assisted ultrasonic spray pyrolysis of hematite mesoporous thin films

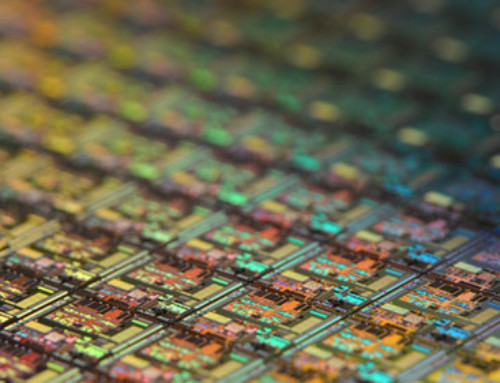

Mesoporous crystalline hematite is a material difficult to prepare by soft-templating with conventional techniques, because of its high crystallization temperature associated to the crystal-to-crystal goethite-to-hematite phase transition. In a previous work, it has been reported that with very careful calcination steps, it is possible to prepare mesoporous hematite films with the spin-coating technique. However, with less conventional techniques such as surfactant-assisted ultrasonic spray pyrolysis, the deposition usually leads to non-porous oxide films or to films with interstitial porosity.

In this work, we demonstrate for the first time the proof-of-concept of block-copolymer templating of hematite thin films by the ultrasonic spray pyrolysis technique. Despite the fast thermal decomposition during spray deposition, a regular, monodisperse packing of spherical pores is observed after deposition on pre-heated substrates (250 °C) and after a careful post-annealing step at 470 °C. Moreover, with the use of a silica scaffold, we successfully preserved porosity up to a temperature as high as 800 °C. These films are highly crystalline and they are composed by randomly oriented nanocrystallites with sizes as small as 25 nm. Furthermore, we show that the crystallization evolution with temperature is influenced by the presence of the templating agent and also by the preparation technique.

Ultrasonic Spray Pyrolysis of Thin Films Video

Recommended Equipment

Ultrasonic Atomization Nozzle

Laboratory Ultrasonic Coating System

UAM3000 Ultrasonic Medical Devices Spraying

UAM4000 Desktop Ultrasonic Spraying Equipment

UAM4000L Benchtop Ultrasonic Spray System

UAM6000 Ultrasonic Spraying Machine

UAL100 Ultrasonic Dispersion Syringe Pump

LULP500 Ultrasonic Laboratory Device

Prosonic1000 Industrial Ultrasonic Device

Prosonic3000 Most Powerful Ultrasonic Processor