Project Description

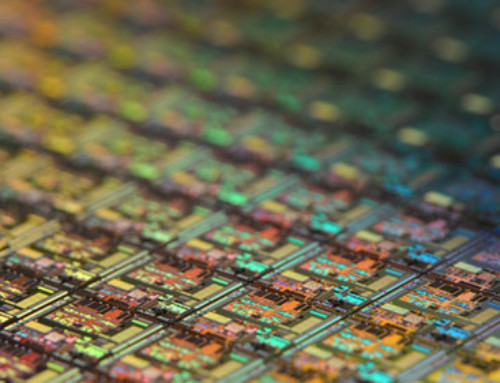

Ultrasonic Spray Photoresist

Photoresists, also known as photoresists, are light-sensitive mixed liquids composed of a photosensitive resin, a sensitizer, and a solvent. It is widely used in the fields of integrated circuits, solar photovoltaics, and micro-electromechanical systems.

Highly uniform photoresist films are often prepared by a spin coating process. The photoresist film made by the spin coating process is determined by the viscosity of the photoresist, the surface tension, and the rotational angular velocity of the turntable. Most photoresists are wasted from the wafer surface due to centrifugal force during spin coating, so the photoresist utilization is extremely low.

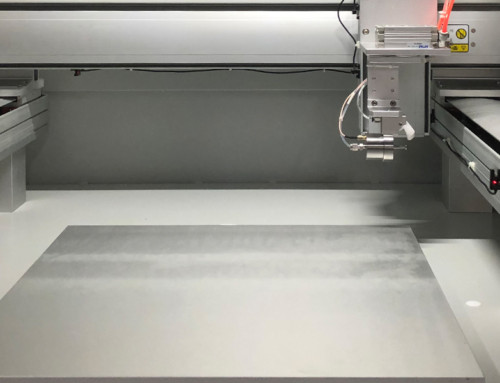

Ultrasonic atomization spraying equipment developed by Chifei Ultrasonic has greatly improved the spraying process of photoresist for the material waste and environmental pollution caused by the traditional rotary coating process of photoresist.

Ultrasonic Spray Photoresist Equipment has low power consumption, and the atomized droplets produced have a small average particle size and good uniformity. The photoresist is directly sprayed on the surface of the wafer, so it is considered to be a green color. Photoresist film preparation process.

The atomized droplets on the surface of the ordinary ultrasonic atomizing spraying device have a small initial velocity and are easily interfered by the surrounding air, which is disadvantageous for obtaining a high-quality photoresist film, so that it is difficult to achieve an ideal spraying effect. Therefore, we add a carrier gas module to the ultrasonic atomizing spray equipment to increase the power of the atomized droplets, control the direction and range of the atomization spray, and realize the directional spraying of the photoresist film on the wafer surface of the substrate. It also avoids environmental pollution and subsequent handling problems.

Ultrasonic Spraying Video