Project Description

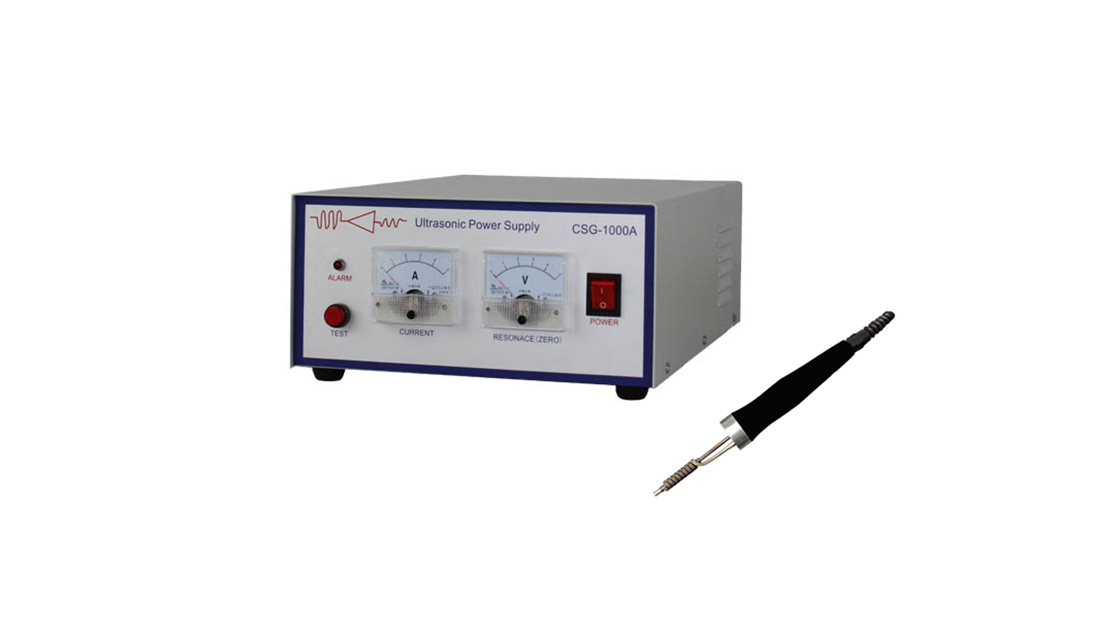

CS55-X100 Ultrasonic Soldering Iron System

Ultrasonic Soldering Iron System is a fluxless process, utiizing acoustically driven mechanical engery to fracture and disrupt oxide films on solder and base materials to promote solder wetting and and adherence. Flux can contaminate and damage/corrode senstive materias, so fluxless soldering is advantageous.

Ultrasonic soldering provides the ability to join most any metal to any other metal, such as a tungsten wire to a stainless steel leadframe, or a copper wire to a nickel tab. Joints will be limited in operating temperature based on the particular solder used. However, all solders can be used with ultrasonic soldering, including lead-free and zinc-based solders.

APPLICABLE INDUSTRIES

ENERGY

- FUEL CELL

- THIN FILM SOLAR CELL

- SILICON SOLAR CELL

ELECTRONICS

- SPRAY FLUX

- SEMICONDUCTOR

- TOUCH SCREEN

Features

• ECO friendly soldering solution: Flux and flux-cleaning process are not needed.

• Perfect Soldering: No Flux Soldering, highly Solid and Reliable Soldering Joint

• Production Cost Savings & High Productivity

• Support of New Application Development: Applying to Solar Cell Glass, Semiconductor, Ceramic Heater, Soldering of Dissimilar Materials (Al-Cu, Al-Glass, Al-Ceramic)

Basic Specifications

• Frequency: 55KHz

• Output power: 100 Watt

• Max amplitude: 8μm

• Operation panel: working temperature, power adjust switch

• Max temperature: 500℃

• Display: amplitude, power, set temperature, current temperature