Project Description

Ultrasonic Solar Glass Coating

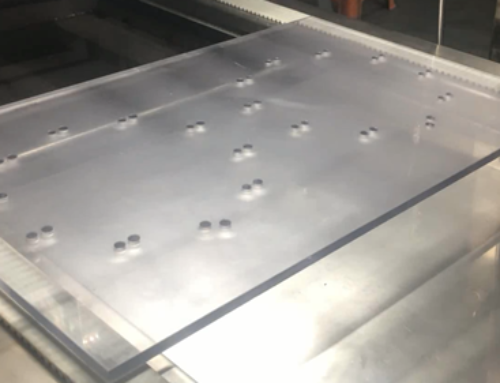

CHEERSONIC ultrasonic development ultrasonic atomization spray system, equipment for the preparation of thin film solar cell uniform film. Ultrasonic spraying is an economical alternative to CVD and sputtering equipment. It provides functional coating coatings that are comparable to vapor deposition systems. The cost and complexity of vapor deposition systems is much higher. Ultrasonic spraying uses twice as much effective material than CVD.

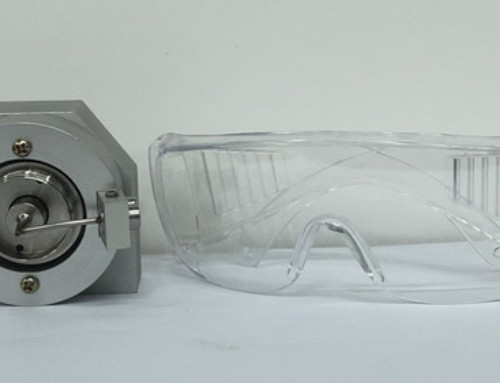

Ultrasonic nozzle advantages:

• Environmentally friendly spray

• Material consumption reduced to 80%

• Stable and consistent spray results

• Can spray nanomaterials

• Minimal maintenance and downtime

• Highly uniform nanofilm

• Precise, non-clogging ultrasonic spray technology is proven in solar glass manufacturing processes

• Precise control of coating thickness