Project Description

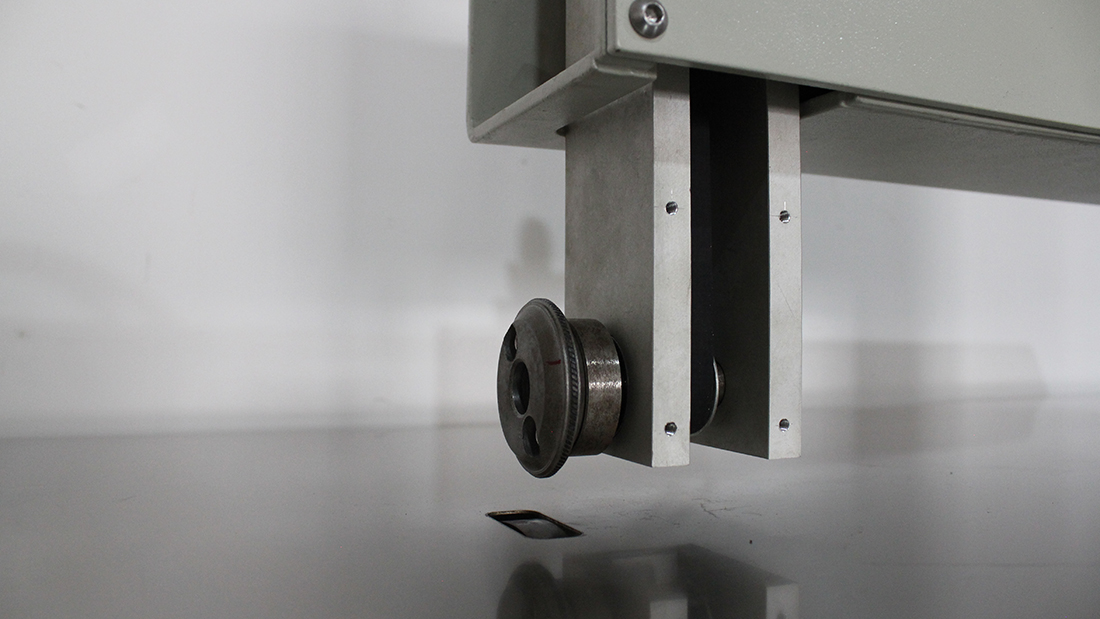

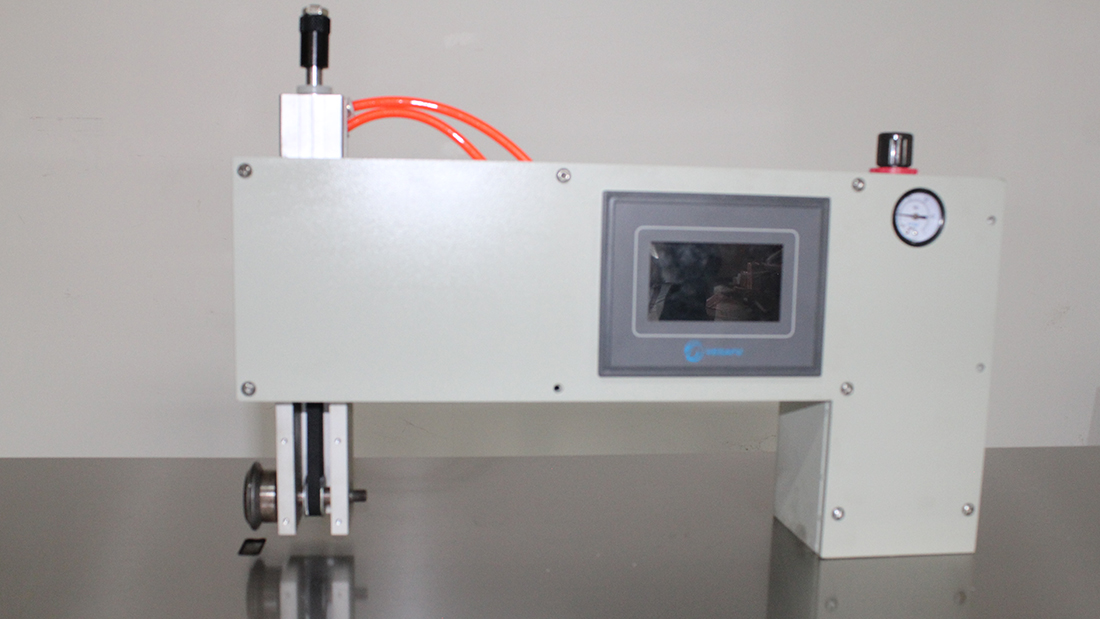

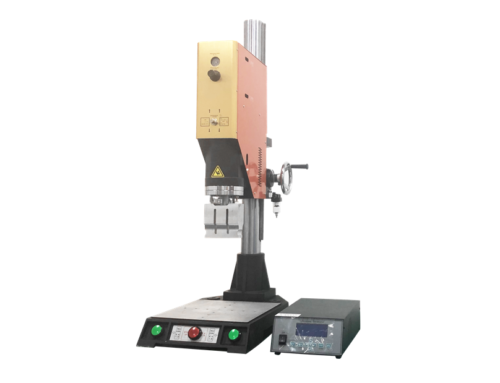

Ultrasonic Sewing System

Principle

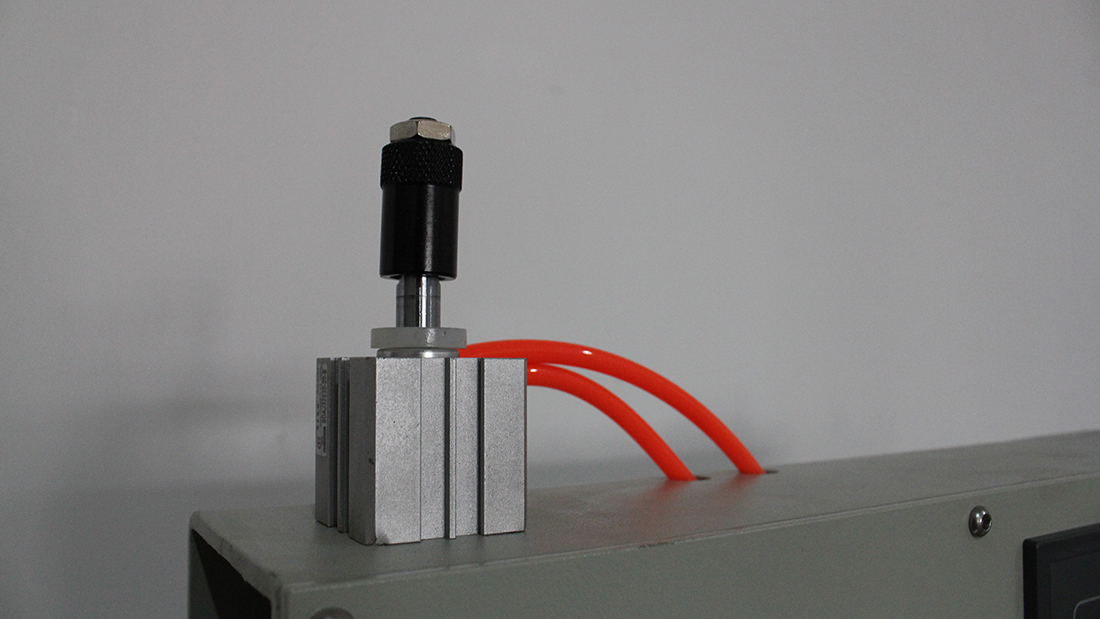

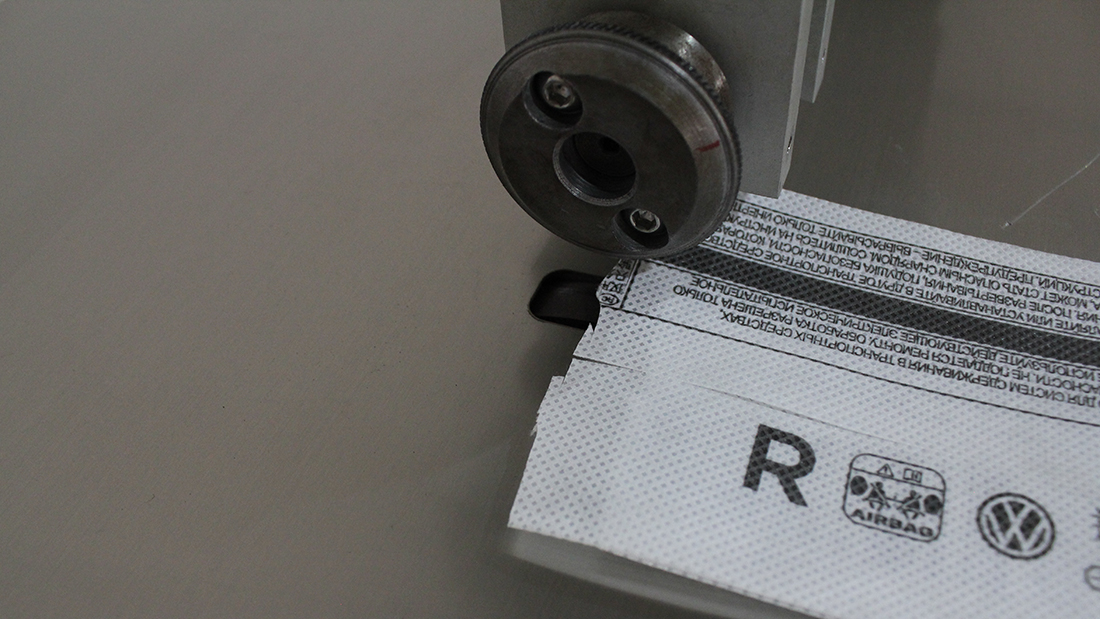

Ultrasonic sewing is the ultrasonic generator to 50/60 Hz current into 15,20,30 or 40 KHz power. The converted high-frequency electrical energy is again converted into mechanical motion at the same frequency by the transducer, whereupon the mechanical movement is transmitted to the welding head by means of a set of amplitude-changing means which can change the amplitude. The welding head transfers the received vibration energy to the joint of the workpiece to be welded, in which the vibration energy is converted into thermal energy by friction and melted and stitched.

Application

It is mainly used for sewing seam, sewing, cutting and embossing of synthetic fiber cloth. It has good watertightness, high production efficiency, no needle and thread accessories, smooth and no burr in melting surface, and good hand feel. Ultrasonic lace sewing machine is widely used in clothing, toys, food, environmental non-woven bags, masks (cup masks, plane masks, three-dimensional masks, etc.) and other industries.

Advantage

• Ultrasonic sewing machine with wear-resistant, long life and so on.

• Operation without preheating Continuous processing, fast, mass production, turning, processing without smoke, sparks, do not harm the fabric edge.

• The machine is easy to operate, easy to understand, ordinary workers can operate on the machine.

• The use of 20KHZ low-noise ultrasonic, anti-noise interference.

• Ultrasonic sewing machine will sew all kinds of fabrics directly, at the same time as trimming, hole, print, so that a product forming, no edges, no bulk.

• Using ultrasonic directly on the various types of materials on the package edge, bronzing, pressing all types of graphics, according to different fabrics, thickness regulation of power.

• Multiple units can be combined into a dedicated machine, in order to complete the width of the larger products, such as the cover, umbrella and so on.