Project Description

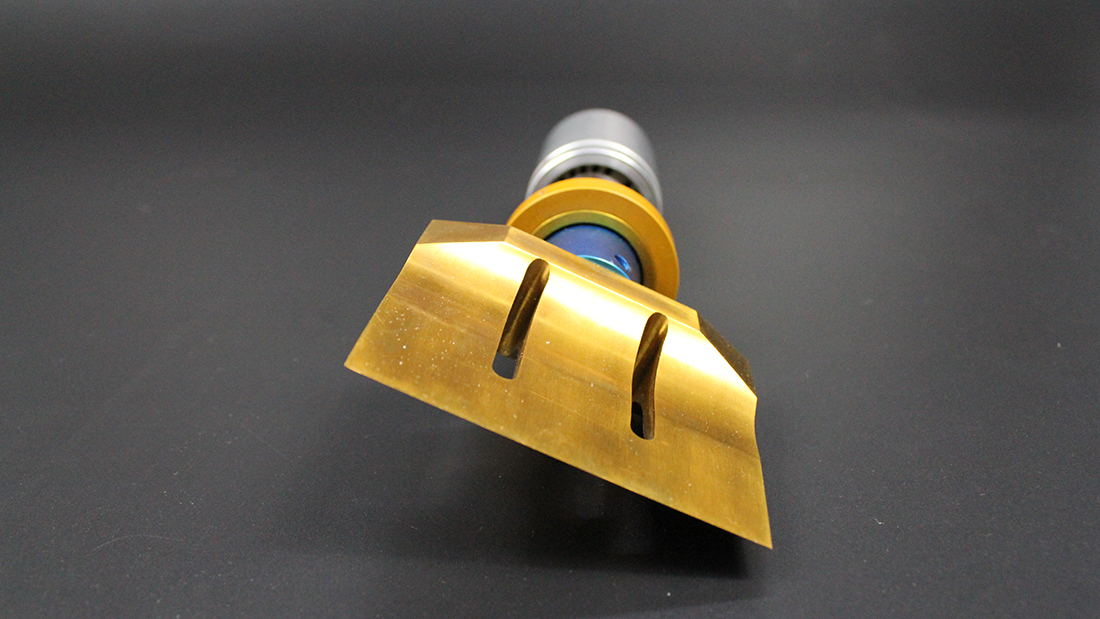

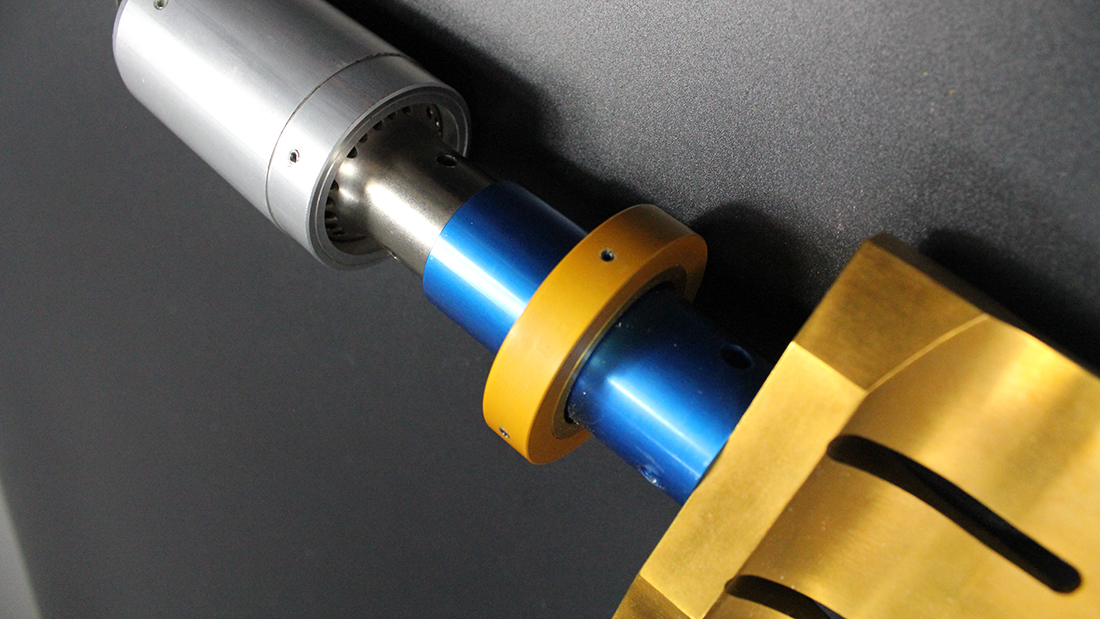

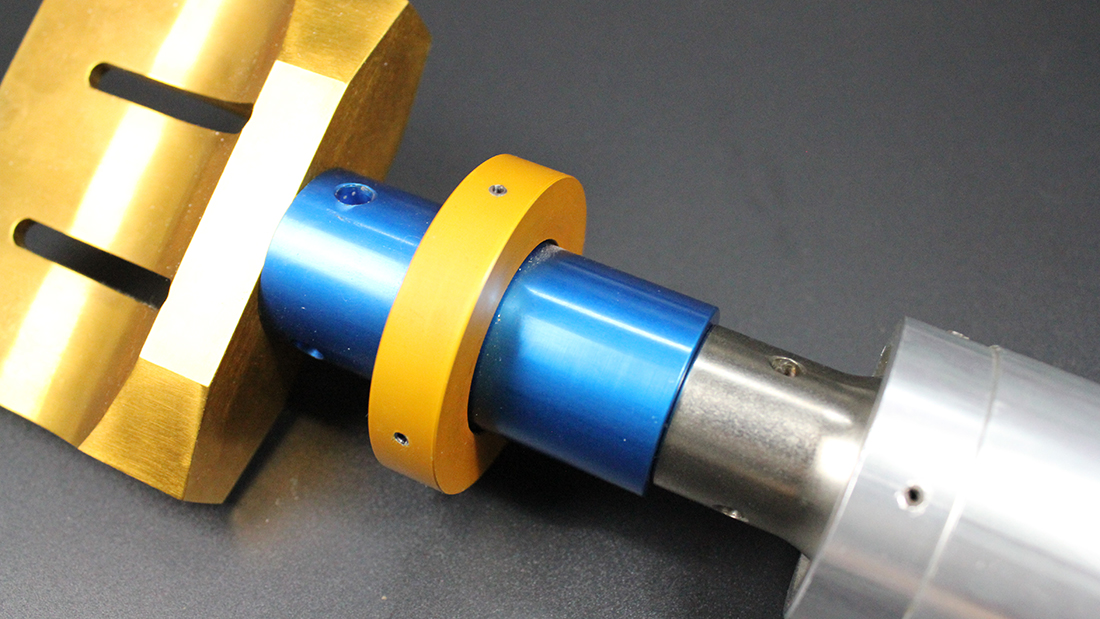

Ultrasonic rubber cutting principle is through the ultrasonic generator 50 / 60Hz current into 20,30 or 40kHz power. The converted high frequency electrical energy is again converted into mechanical vibrations of the same frequency by means of transducers, which are then transmitted to the cutter through a set of amplitude modulator means which can vary the amplitude. The cutter transmits the received vibration energy to the cutting surface of the workpiece to be cut, in which the vibration energy is cut by activating the molecular energy of the rubber and opening the molecular chain.

Advantages

• High cutting accuracy, no deformation of the compound

• High speed, high efficiency, no pollution

• Cutting surface finish is good, good bonding performance

• Easy to use in automated production

Applications

Used in tire, cable foreskin materials, hoses, gaskets and chemical-resistant equipment lining and other rubber products, cutting.

Choice of Cutting Method:

20kHz cutting knife in the upper tread cutting (which can be cross-cutting and longitudinal mode)

• A suitable amplitude and feed rate increase the cutting quality

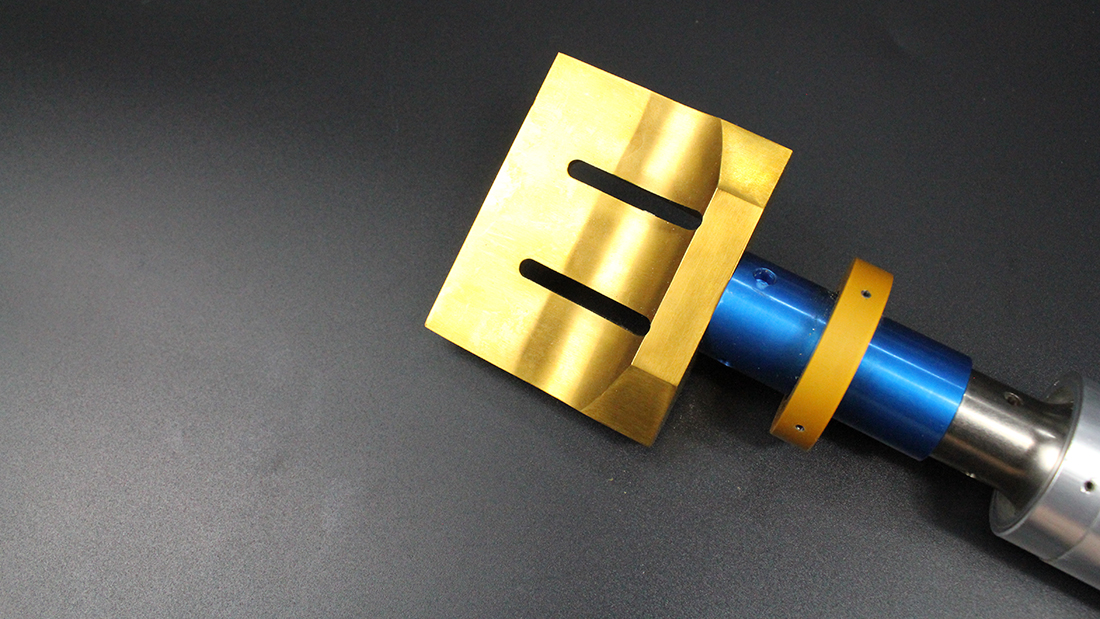

• The key factors affecting the cutter are the knife’s angle, size, shape and thickness

• High power, more suitable for high-class cars, car tread cutting

• Common cutter types: 100mm, 255mm, 305mm, 350mm and other cutting knife

Cut the sidewall of the tire rubber using a 40 kHz cutter (typically in a cross-cutting mode)

• The cutting speed depends on the angle and thickness of the cut tire rubber

• The key factors affecting the cutter are the knife’s angle, size, shape and thickness

• For semi-steel tires, radial tires and other inner liner and sidewall cutting

• Common types of cutter: 82mm and other cutting knife

| Model | Frequency | Power | Knife Width | Knife High |

| URC82 | 40khz | 500watt | 82mm | 70mm |

| URC100 | 20khz | 800watt | 100mm | 128mm |

| URC255 | 20khz | 1000watt | 255mm | 128mm |

| URC305 | 20khz | 1500watt | 305mm | 128mm |