Project Description

Ultrasonic Preparation – Graphene Transparent Conductive Film

In recent years, transparent conductive films are widely used in flat panel displays, solar cells, light emitting devices and other optoelectronic fields.

Graphene has high electron mobility at room temperature, excellent electrical conductivity, high transmittance in the visible and near-infrared range, excellent thermal conductivity, stable chemical properties, good mechanical flexibility and low manufacturing cost, deposited on a flexible substrate On the graphene film can replace the traditional conductive film, and it also has the traditional conductive film does not have the flexibility of the performance.

Currently, graphene flexible transparent conductive films are mainly prepared by vacuum evaporation, sputtering and ion plating.

Thin films obtained by vacuum evaporation have small grain sizes, large resistivity and low visible light transmittance; The sputtering method has the advantage that any substance can be sputtered, especially a high melting point, low vapor pressure element or compound , The adhesion between the thin film and the substrate is good, but the disadvantage is that the sputtering equipment is complex; The advantage of ion plating is that the deposition speed is relatively fast, the film can be prepared relatively uniformly, and the disadvantage is that the ionization degree needs a very high accelerating voltage, Less ion is not conducive to the reaction deposition.

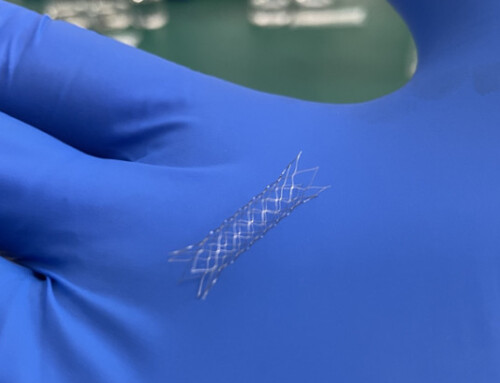

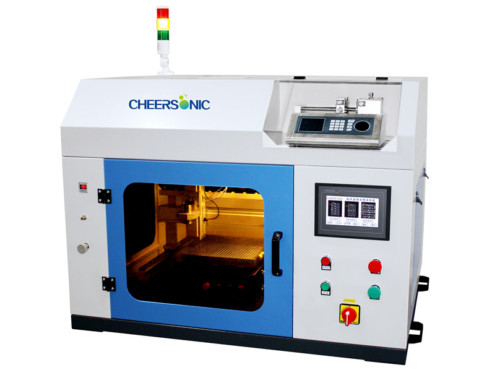

CHEERSONIC Ultrasonic Preparation of Graphene Organic Solvent Dispersion by Ultrasonic Nanoprocessing Apparatus. Ultrasonic atomization spray equipment sprayed on the PET substrate, the use of ultrasonic spray coating uniformity, so that the solution completely spread, and then dried at room temperature to obtain a graphene film.

Ultrasonic atomization spray coating equipment Graphene film, CHEERSONIC ultrasonic inspection and analysis with UV spectrometer and found that the entire scanning spectral region of graphene without any absorption peak, it can be seen that ultrasonic atomization spray method does not introduce other chemical bonds, that is, there is no The introduction of oxygen atoms, graphene will not be oxidized, so prepared graphene film purity, good quality. In addition, graphene film thickness controllable repeatability, graphene film hole rate is low, porosity is small, and the film coating and PET substrate adhesion between the good, not easy to stripping.