Project Description

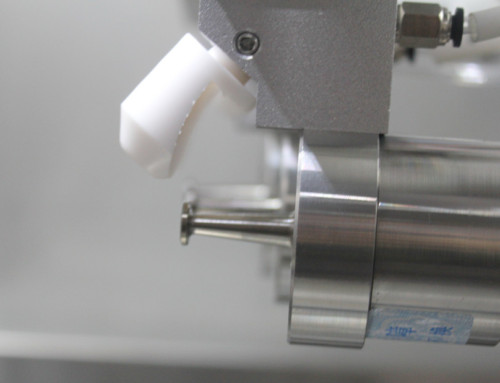

Ultrasonic Paint Dispersion Equipment

Paint and Coating

So-called coating is coated on the surface of the object that be protected or be adornment, and with the continuous film coating to form strong adhesion, usually in resin, or oil, or emulsion is given priority to, add or not add pigment, filler, add the corresponding additives, organic solvents or water preparation of viscous liquid.

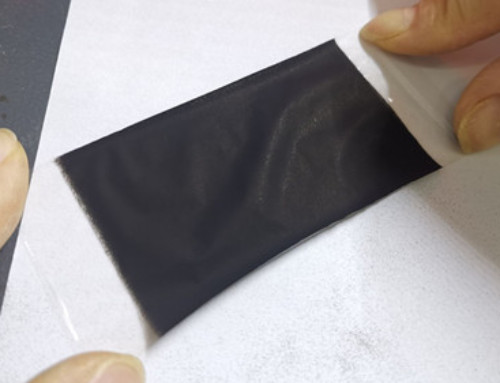

Paint and Coating Dispersion Results

Ultrasonic dispersion equipment, as a kind of new method has been used to enhance the efficiency of the machining of paint in the production and processing, it has the following advantages: lower dyeing temperature, reduce the processing time, reduce the dosage of chemical fertilizer, increase the amount of color. But not many ultrasonic research also showed a similar effect.

The Effect of Ultrasonic Dispersion Machine

The mechanism of the ultrasonic dispersing equipment from ultrasonic cavitation effect. Ultrasonic cavitation is refers to the tiny air bubbles in the liquid formation, growth, collapse and cause of physical and chemical effect. In the process of the collapse of the bubble can release enormous energy, micro jet speed as high as 110 MPS, has strong impact. Cavitation bubbles at the instant of the explosion can produce up to 5000 k or even 10000 k more than more than 100 mpa and local high temperature and high pressure environment, the heating and cooling rate of more than 1010 KPS. These extreme conditions to make coating molecular bond rupture is reunited, promote the dispersing rate of reaction of coating, coating grain size control and distribution.