Project Description

Ultrasonic LED Phosphor Spray Process

LED has gradually replaced the traditional light source because of its characteristics of energy saving, high efficiency and long life.

High-power white LED by the blue LED chip excitation in the surface of the phosphor powder produced, of which phosphor powder has a high viscosity.

There are many ways to apply the phosphor to the LED chip surface, each with its own advantages and disadvantages. For example, in the crystal-level phosphor coating process, it is difficult to apply the phosphor glue quickly and uniformly to the LED chip by using the traditional dispensing method. LED chip phosphor layer coating uneven, will seriously affect the high-power white LED light color quality and luminous efficiency, and LED life.

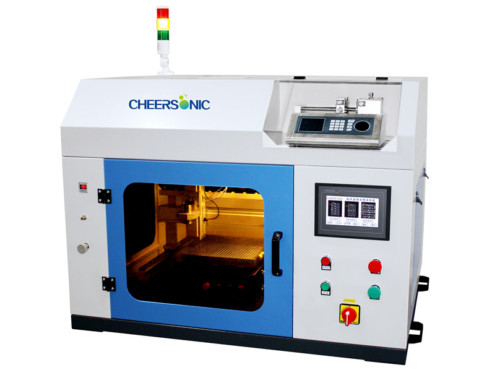

CHEERSONIC ultrasonic research and development of ultrasonic atomization spray equipment phosphor powder coating.

Ultrasonic technology through the choice of different power ultrasonic atomization spray equipment can control the phosphor atomization range of 14 ~ 80μL. In the process of spraying phosphor, the phosphor powder is vibrated by the high-frequency ultrasonic wave into fine droplets in the atomization channel, the atomizing nozzle is sprayed onto the surface of the LED chip, and then the phosphor powder droplets collide, deposit and solidify in a very short time LED chip surface, forming a high-quality phosphor layer, to ensure its luminous efficiency.

High-efficiency, low-cost, high-quality ultrasonic spray equipment will also be widely used in other electronic equipment coating process.