Project Description

Ultrasonic Interventional Stent Spraying

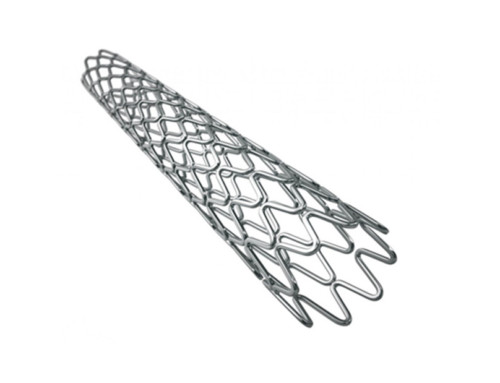

Ultrasonic Interventional Stent Spraying. The characteristics of the bracket: the surface is not flat, and the geometric shape is complex.

Traditional spraying method: dip coating method. Dip coating will cause waste of drugs, and energy consumption will be consumed in the air drying process. Ultrasonic spraying reduces the waste of drugs and avoids energy consumption.

At present, the application of ultrasonic sprayed blood vessel stents is relatively mature.

Ultrasonic spray intervention stent case: We take coronary artery stent grafting as an example. Ultrasonic application to the vascular stent nozzle is currently based on 120KHZ. At this frequency, the particle diameter is 18um. The spray diameter is 0.04mm. Currently spraying the blood vessel stent The whole machine is UAM3000 ultrasonic atomizing spraying equipment.

Ultrasonic Features:

1. Reduce waste: Ultrasonic use of medical textiles saves drugs compared to traditional dip coating

2. Atomization uniformity: Ultrasonic sprayed slides are more uniform than traditional high pressure spray

3. Small atomized particles: smaller particle diameter helps microcapsules to play a role in more fields

4. Not easy to block

Ultrasonic Interventional Stent Spraying

Recommended Equipment

Ultrasonic Atomization Nozzle

Laboratory Ultrasonic Coating System

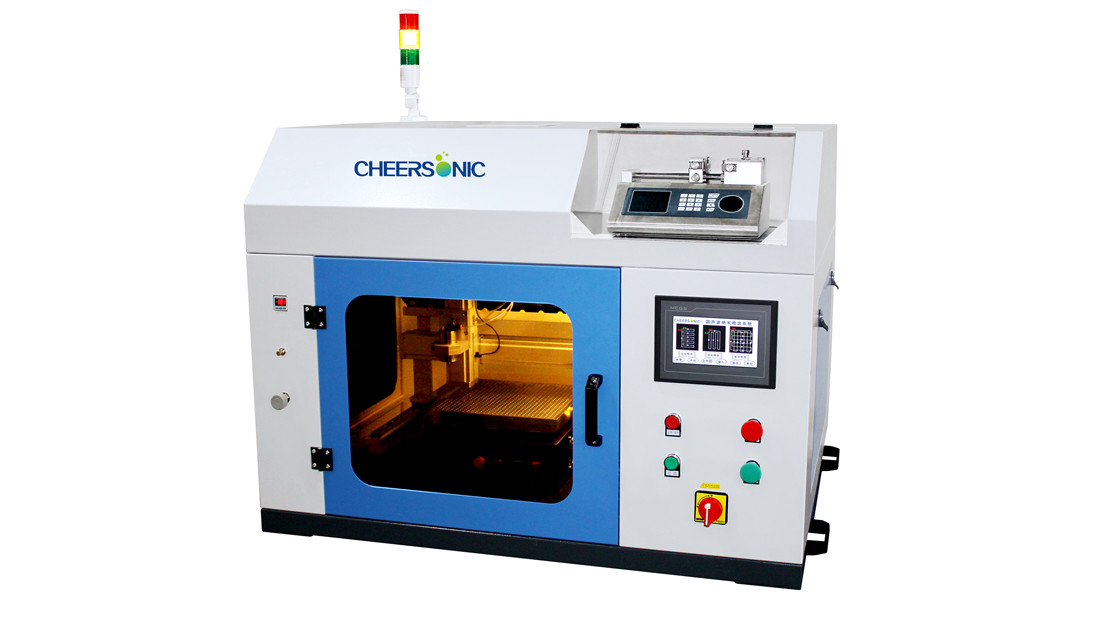

UAM3000 Ultrasonic Medical Devices Spraying

UAM4000 Desktop Ultrasonic Spraying Equipment

UAM4000L Benchtop Ultrasonic Spray System

UAM6000 Ultrasonic Spraying Machine

UAL100 Ultrasonic Dispersion Syringe Pump

LULP500 Ultrasonic Laboratory Device

Prosonic1000 Industrial Ultrasonic Device

Prosonic3000 Most Powerful Ultrasonic Processor