Project Description

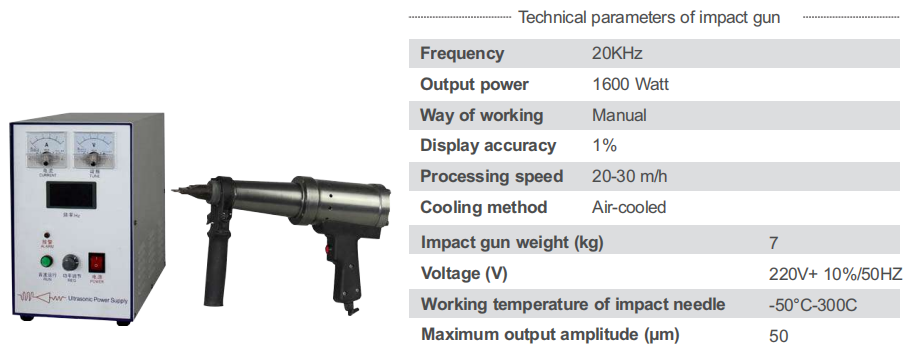

Ultrasonic Impact Treatment

Introduction

Ultrasonic impact treatment equipment is regularly and successfully used in many sectors: aerospace, energy, automotive, defence, transportation and infrastructure.

Advantage

• Correction Of Distortions Due To Welding

• Improve Fatigue Resistance

• Increase In Stress Corrosion Cracking Resistance

IMPROVED FATIGUE RESISTANCE

Ultrasonic Impact Treatment is a high-frequency weld impact treatment designed to improve the fatigue resistance of welded structures. It is a cold mechanical treatment that involves striking the weld toe with a needle (or striker) to create an enlargement of its radius and to introduce residual compressive stresses.

INCREASE IN STRESS CORROSION CRACKING RESISTANCE

The creation of superficial compression, by peening, due to the impact of the needles on the material also makes it possible to improve the resistance for stress corrosion cracking.

CORRECTION OF DISTORSIONS DUE TO WELDING

The stresses created by welding processes cause distortions in the welds between the panels. These well-known distortions occur during the cooling phase of the weld, when the molten metal shrinks, resulting in plastic deformation of the welded metals.