Project Description

Product Description

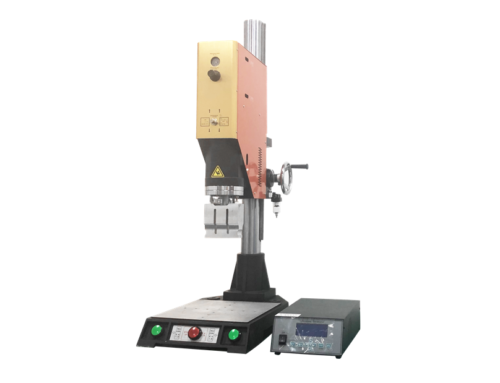

Ultrasonic Fabric Cutting Machines are composed of the basic structure of ultrasonic transducers, ultrasonic horn, ultrasonic cutting knife, ultrasonic generator. Ultrasonic generator, electricity into high-frequency high-voltage AC current, lost to the ultrasonic transducer. Ultrasonic transducer, the equivalent of energy conversion devices, it can convert the input electrical energy into mechanical energy, that is, ultrasound. Ultrasonic transducer in the longitudinal back and forth stretching movement, telescopic movement frequency is equivalent to the drive power supply frequency of high frequency AC current. Ultrasonic horn, ultrasonic horn will ultrasonic transducer output amplitude amplification. Ultrasonic cutting knife to further amplify the amplitude, focusing ultrasound, ultrasonic output, the use of cutting-edge ultrasonic energy into the cutting material to be cut into parts. The site in the role of a huge ultrasonic energy, instant softening, melting, strength greatly reduced. Only a small force can be applied to cut the material.

Advantages

• Ultrasonic cutting machine features, do not need sharp blades, do not need a lot of pressure, will not make cutting material damage.

• The use of ultrasonic cutting, incision aesthetic integrity, trimmed neatly smooth, burr-free.

• At the same time, the cutting part has fusion. The cutting site is perfectly sealed to prevent loosening of the material to be cut.

Applications

Used in a variety of textile materials