Project Description

Ultrasonic Energy-Saving Photoresist Precision Spraying Equipment

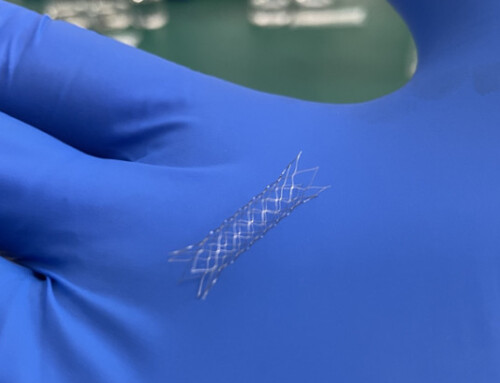

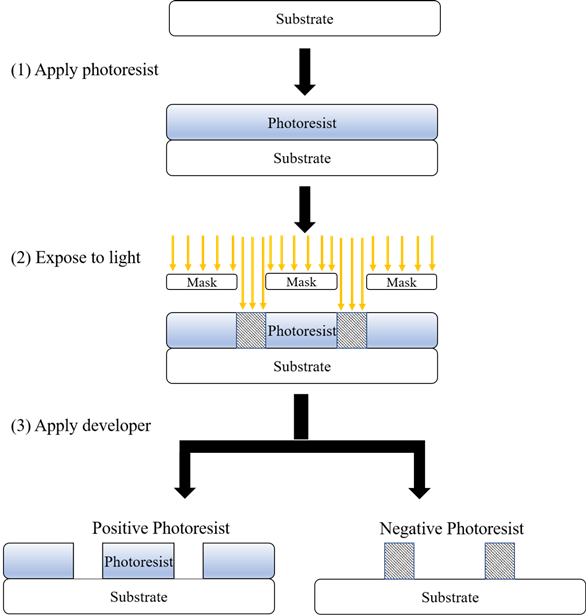

Photoresist, also known as photoresist, is a photosensitive mixture composed of photosensitive resin, sensitizer and solvent. It is widely used in the fields of integrated circuits, solar photovoltaic, MEMS and other fields.

High uniformity of the photoresist film and more spin coating process. The final thickness of the photoresist film obtained by the spin coating process is determined by factors such as the viscosity of the photoresist, the surface tension and the rotational angular velocity of the turntable. Most of the photoresist is thrown away by the centrifugal force during spin coating Wafer surface, resulting in waste, so photoresist utilization is very low.

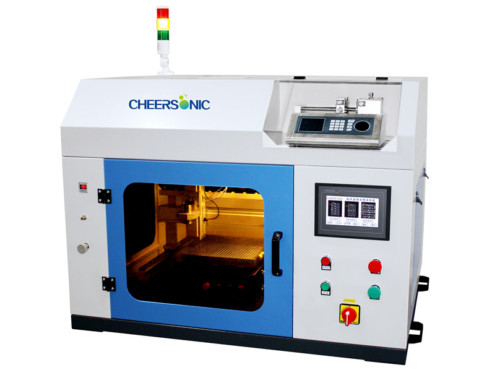

In view of the waste of the photoresist coating process (spin coating process) and environmental pollution problems, CHEERSONIC ultrasonic has improved the photoresist coating process based on the 120KHZ ultrasonic atomization spraying equipment developed by ourselves.

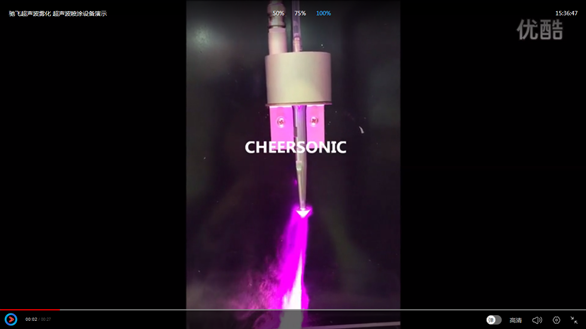

Ultrasonic atomization spray equipment power consumption (10W) low, resulting in atomized droplets of small average particle size, good uniformity, the direct application of droplets on the wafer surface photoresist utilization, it is considered to be A green photoresist film preparation process. However, the atomized droplets on the surface of an ordinary ultrasonic atomizing spraying device have a small initial velocity and are easily disturbed by the ambient air, which is not conducive to obtaining a high-quality photoresist film and is difficult to achieve an ideal spraying effect. For this purpose, CHEERSONIC ultrasonic adds a carrier gas module to the ultrasonic atomizing spraying equipment to increase the power of the atomized liquid droplets and control the direction and the range of the atomized spraying so as to achieve the directional coating of the photoresist film on the surface of the substrate.

CHEERSONIC ultrasonic precision spraying equipment to achieve the directional photoresist coating, saving 90% of the photoresist material, to avoid environmental pollution and follow-up of the issue.