Project Description

Ultrasonic Coating Systems for Fuel Cells

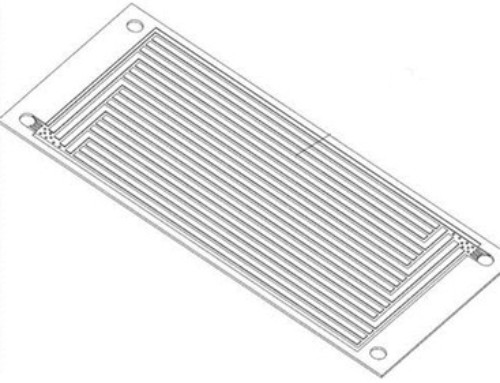

Ultrasonic Coating Systems for Fuel Cells. Ultrasonic nozzles are ideal for spraying catalyst layers onto a variety of fuel cell substrates, including PEM, GDL, electrodes, various electrolyte membranes, solid oxide fuel cells (SOFC), rods and buttons with ceramic paste or containing carbon black. A catalyst suspension of ink or other conductive ink such as platinum, nickel, rhodium or ruthenium.

The uniform film coating achieved with ultrasound preserves the porosity of the electrode and does not interfere with the transport of reactants due to flooding of the electrode surface. The catalyst solution does not block the ultrasonic nozzles, enabling precise coatings with controlled droplet sizes at ultra-low flow rates.

Ultrasonic Advantage

Non-blocking technology

Ability to optimize droplet size with tight droplet distribution

Agglomeration of the particles in the solution results in a more uniform coating. The ability to change the morphology of the coating.

Precision Spraying Machine Video