Project Description

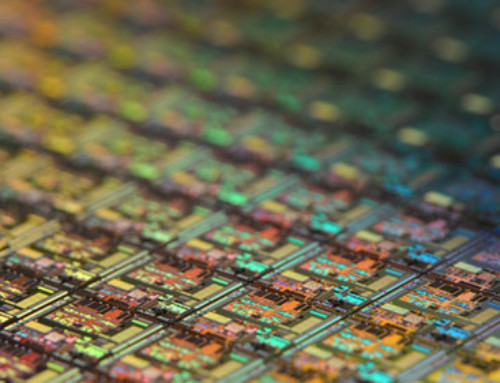

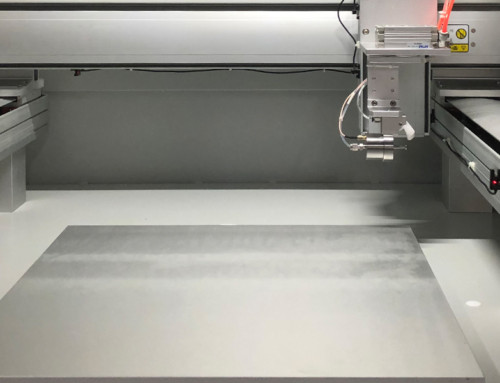

Substrate Coating

Cheersonic nozzles can be utilized to coat a variety of substrates with a variety of liquids, solutions, suspensions, emulsions, etc. for various applications. Automated robotic coating systems allow for precise, accurate, reproducible, and repeatable coatings of substrates, in single, batch, or continuous process settings. Automation combined with hypo-needle feed attachments allow for multiple materials to be used in a coating during a single run, whether sequentially, simultaneously, or otherwise, allowing for graded coatings or bondcoats, or potentially even single nozzle use for multilayer coatings, which may be particularly useful for photovoltaic or solid oxide fuel cell applications. Such automated systems may even be utilized for spray based 3D printing of hydrogels or polymers from solution precursors and bioprinting, as well as for medical diagnostic and test substrates or other coatings of biomedical interest such as those for medical stents, catheters, or biomedical implants. Cheersonic ultrasonics builds and develops automated coating systems from the laboratory and benchtop scale up to production level.

Ultrasonic Spraying Video

Recommended Equipment

Ultrasonic Atomization Nozzle

Laboratory Ultrasonic Coating System

UAM3000 Ultrasonic Medical Devices Spraying

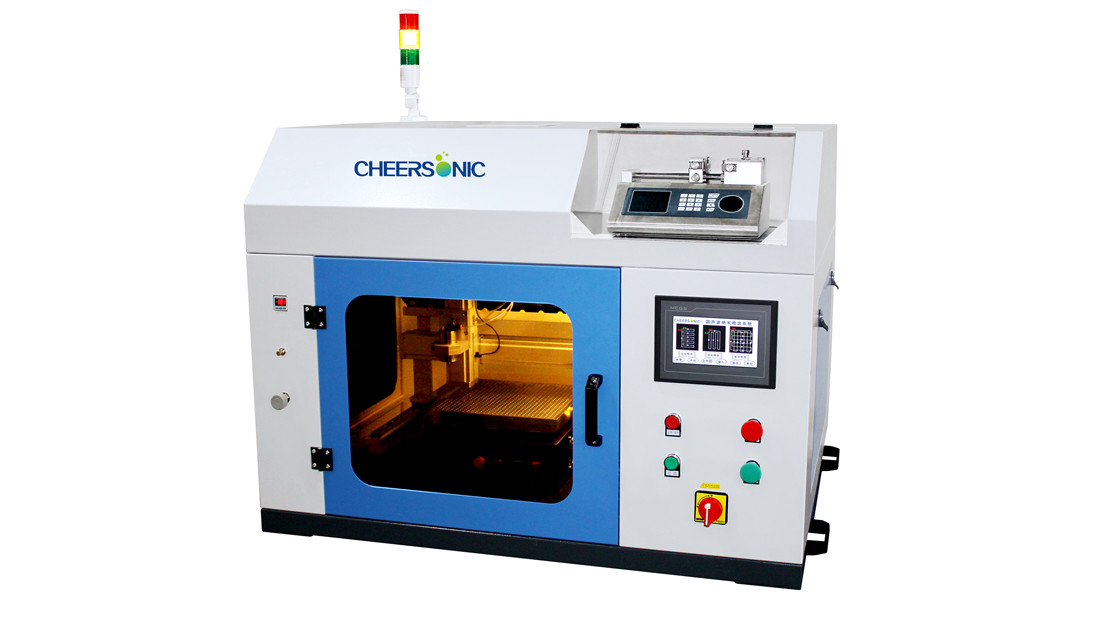

UAM4000 Desktop Ultrasonic Spraying Equipment

UAM4000L Benchtop Ultrasonic Spray System

UAM6000 Ultrasonic Spraying Machine

UAL100 Ultrasonic Dispersion Syringe Pump

LULP500 Ultrasonic Laboratory Device

Prosonic1000 Industrial Ultrasonic Device

Prosonic3000 Most Powerful Ultrasonic Processor