Project Description

Conventional cutting is performed with a tool having a sharp cutting edge to press against the material to be cut. This pressure concentrated in the edge, the pressure is very large, more than the shear strength of the material being cut, the material of the combination was pulled, was cut off. As the material is a strong pressure to pull hard, so cutting edge should be very sharp, the material itself also have to bear a relatively large pressure. The soft, flexible material cutting effect is not good, more difficult for viscous materials.

Compared to traditional food cutting knife, ultrasonic cutting does not require a sharp edge, do not need a lot of pressure, will not cause food damage. At the same time, because the cutting knife in doing ultrasonic vibration, friction resistance is particularly small, the cutting material is not easy to stick on the blade. This pair of viscous and elastic materials, frozen materials, such as cream cake, ice cream and so on.

Advantages

• Multi-layer products cut, can maintain the level of cross-color.

• Ultrasonic cutting advantages: incision delicate, can not afford to chip, non-stick knife.

• Cuttable: Sheet, Rectangle, Triangle, Equal Circle.

• Wide range of cutting objects, frozen products, including cream products can adapt.

• Custom cutting models can be customized to meet customer requirements.

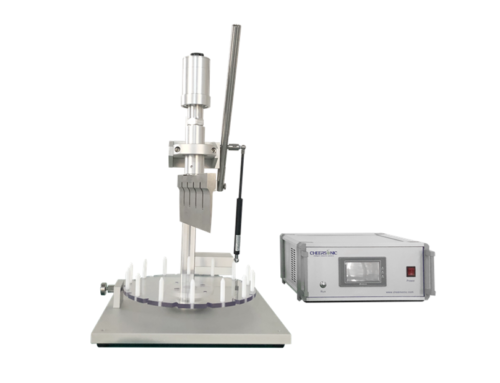

Applications

Used in cakes, cheese, pizza, sandwiches and other cutting. (Click here for more applications)

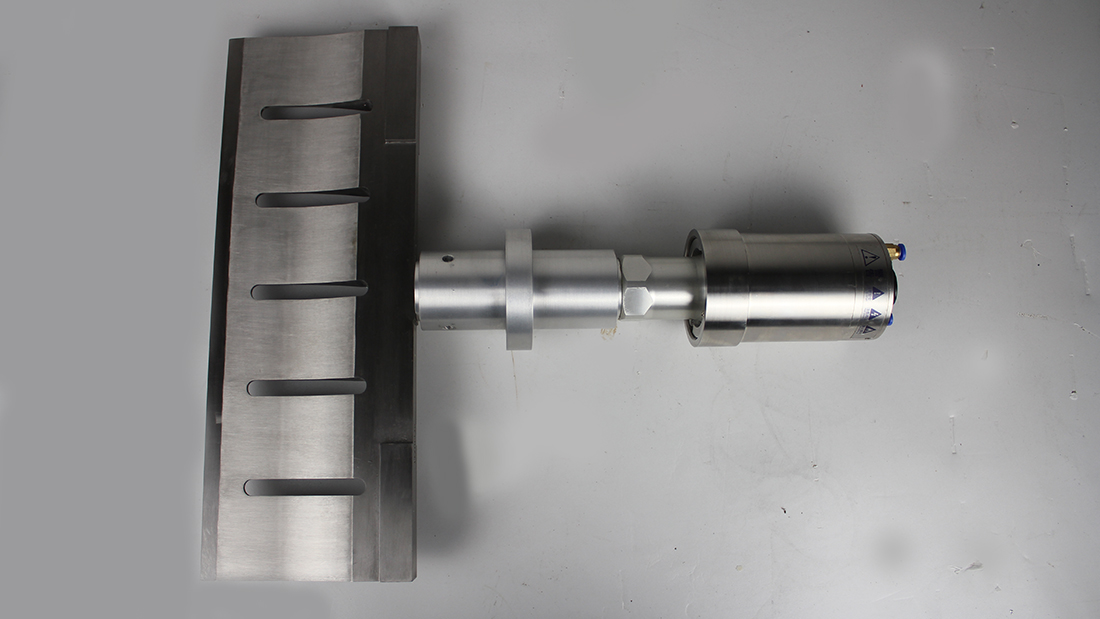

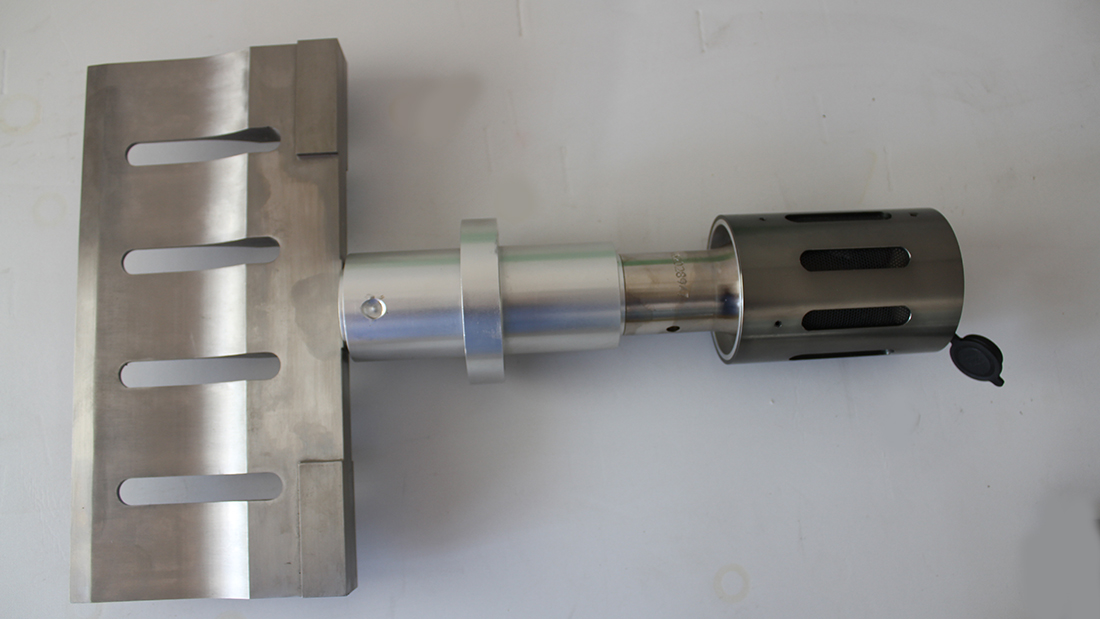

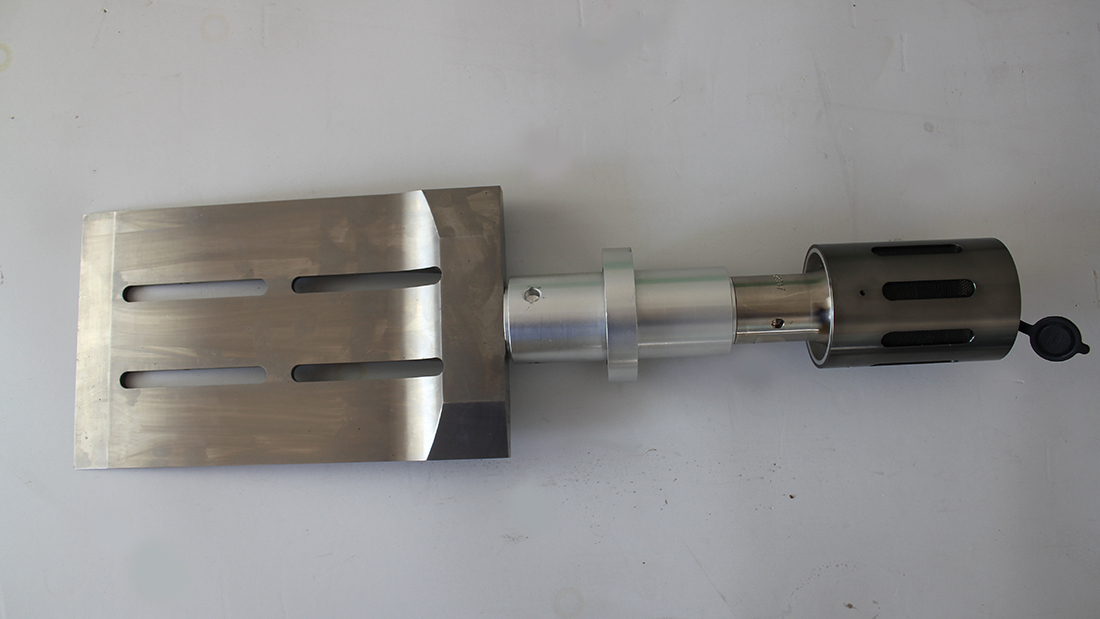

| Ultrasonic Blades Model | Frequency | Power | Blade Height | Blade Width |

| UFC80 | 40khz | 500watt | 80mm | 70mm |

| UFC100 | 20khz | 800watt | 100mm | 128mm |

| UFC152 | 20khz | 1200watt | 152mm | 258mm |

| UFC255 | 20khz | 1000watt | 255mm | 128mm |

| UFC305 | 20khz | 1500watt | 305mm | 128mm |

| UFC350 | 20khz | 1600watt | 350mm | 128mm |