Project Description

Spraying Organic Conductive Film

Lithium ion battery – organic conductive film preparation and spraying – Cheersonic

Lithium Ion Battery

Lithium-ion battery is a kind of rechargeable battery, which mainly relies on the movement of lithium ions between the positive and negative electrodes to work. During the charging and discharging process, Li intercalates and deintercalates back and forth between the two electrodes: when recharging the battery, Li+ deintercalates from the positive electrode and inserts into the negative electrode through the electrolyte, the negative electrode is in a lithium-rich state; the opposite is true during discharge.

Lithium-ion batteries are easily confused with the following two types of batteries:

1) Lithium battery: Lithium is present.

(2) Lithium-ion polymer batteries: replace liquid organic solvents with polymers.

Lithium-ion battery components:

Steel shell/aluminum shell/cylindrical/soft packaging series:

(1) Positive electrode-the active material is generally lithium manganese oxide or lithium cobalt oxide. Nowadays, nickel cobalt manganese oxide materials have appeared. Electric bicycles use lithium iron phosphate, and the conductive current collector uses electrolytic aluminum foil with a thickness of 10-20 microns.

(2) Diaphragm one-a special composite membrane that allows ions to pass through, but is an insulator of electrons

(3) Negative electrode-the active material is graphite, or carbon with a similar graphite structure, and the conductive collector uses electrolytic copper foil with a thickness of 7-15 microns

(4) Organic electrolyte one—carbonic acid ester solvent with lithium hexafluorophosphate dissolved, and gel electrolyte for polymer

(5) The battery shell is divided into steel shell (the square type is rarely used now), aluminum shell, nickel-plated iron shell (used for cylindrical batteries), aluminum plastic film (soft packaging), etc., as well as the battery cap, which is also the battery Positive and negative terminals.

Mechanism of action

Lithium batteries are divided into lithium batteries and lithium ion batteries. Currently both mobile phones and laptops are used

It is a lithium-ion battery, commonly known as a lithium battery, and a real lithium battery is rarely used in daily electronic products because of its high risk.

Lithium-ion batteries use carbon material as the negative electrode and lithium-containing compounds as the positive electrode. There is no metal lithium

Exist, only lithium ion, this is lithium ion battery. Lithium ion battery refers to the general term for batteries with lithium ion intercalation compound as the cathode material. The charging and discharging process of lithium ion batteries is the process of intercalation and deintercalation of lithium ions. In the process of intercalation and deintercalation of lithium ions, it is accompanied by the intercalation and deintercalation of electrons equivalent to that of lithium ions (the positive electrode is usually represented by insertion or deintercalation, and the negative electrode is represented by insertion or deintercalation). During the charging and discharging process, lithium ions are intercalated/deintercalated and intercalated back and forth between the positive and negative electrodes, which is vividly called the “rocking chair battery”.

New development of ionic battery

Polymer lithium ion batteries are developed on the basis of liquid lithium ion batteries, using conductive materials

The latest generation of rechargeable lithium-ion batteries is composed of the positive electrode and the carbon material as the negative electrode. The electrolyte is composed of a solid or gel organic conductive film and is packaged with aluminum plastic film. Because of its more stable performance, it is also regarded as a replacement product for liquid lithium-ion batteries. Many companies are currently producing this new type of battery.

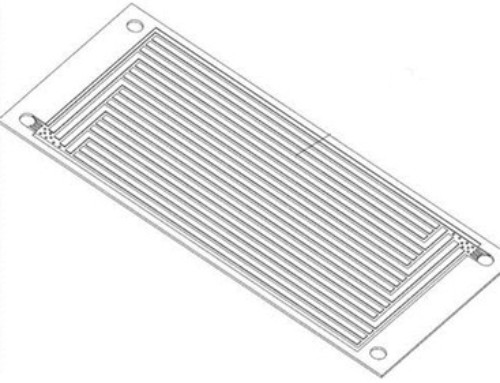

Facts have proved that ultrasonic spray technology can successfully deposit thin films and organic conductive films in polymer lithium-ion batteries. The cost of the ultrasonic atomization spraying system is only a small part of the CVD and sputtering equipment, which can reduce the cost of manufacturing ion batteries while still providing higher battery efficiency. Ultrasonic spray technology has always been a recognized feasible method that can be used to scale up to larger sizes and larger organic conductive films.

Ultrasonic Fuel Cell Coating Video

Recommended Machine

UAL100 ultrasonic dispersion liquid supply system

UAM3000 Ultrasonic Bracket Spraying Machine

UAM4000 small desktop ultrasonic spraying machine

UAM4000L Ultrasonic Precision Spraying Machine

UAM6000 Ultrasonic Large Spraying Machine

UAM7000 Ultrasonic Balloon Guide Wire Spraying Machine

UAM8000 ultrasonic assembly line spraying machine