Project Description

Solid Oxide Fuel Cell Coating Spray

Protective coating based on manganese–copper oxide for solid oxide fuel cell interconnects: Ultrasonic spray coating and performance evaluation

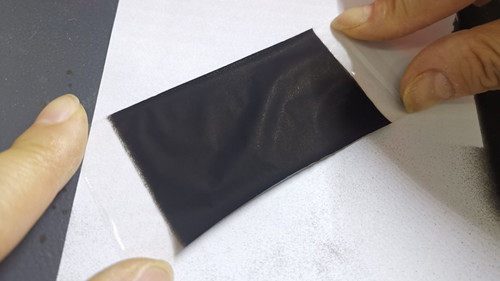

A solid oxide fuel cell (SOFC) stack requires metallic interconnects to electrically connect unit cells, while preventing fuel from mixing with oxidant. During SOFC operations, chromia scales continue to grow on the interconnect surfaces, resulting in a considerable increase of interfacial resistance, and at the same time, gaseous Cr species released from the chromia scales degrades the cathode performance. To address these problems, in this study, protective Mn2CuO4 coatings are fabricated on metallic interconnects (Crofer 22 APU) via a Ultrasonic spray coating process.

The ultrasonic spray coating technique involves direct spray deposition of molten Mn2CuO4 onto the interconnect substrate and leads to the formation of high-density Mn2CuO4 coatings without the need for post-heat-treatment. The thickness, morphology, and porosity of the PS-Mn2CuO4 coating are found to depend on the processing parameters, including Spray frequency, liquid viscosity, and substrate temperature. The PS-Mn2CuO4 coating fabricated with optimized parameters is completely impermeable to gases and has high adhesion strength on the interconnect substrate. Furthermore, no resistive chromia scales are formed at the coating/substrate interface during the Ultrasonic spray coating process.

Proton Exchange Membrane Fuel Cell Spray Video

Recommended Equipment

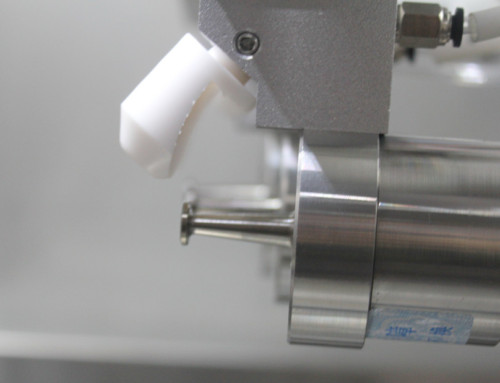

Ultrasonic Atomization Nozzle

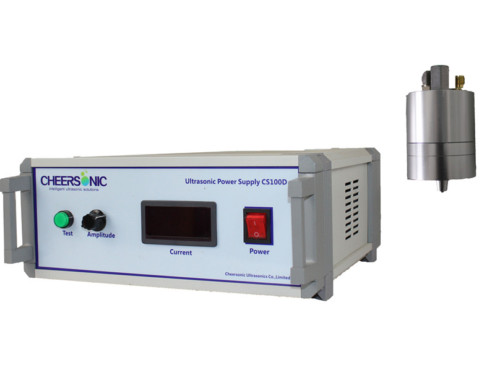

Laboratory Ultrasonic Coating System

UAM3000 Ultrasonic Medical Devices Spraying

UAM4000 Desktop Ultrasonic Spraying Equipment

UAM4000L Benchtop Ultrasonic Spray System

UAM6000 Ultrasonic Spraying Machine

UAL100 Ultrasonic Dispersion Syringe Pump

LULP500 Ultrasonic Laboratory Device

Prosonic1000 Industrial Ultrasonic Device

Prosonic3000 Most Powerful Ultrasonic Processor