Project Description

Proton Exchange Membrane Fuel Cell Coating

Proton Exchange Membrane Fuel Cell Coating – Cheersonic

Proton membrane fuel cell is a new type of fuel cell. Its electrolyte is a solid organic membrane. Under humidification, the membrane can conduct protons. It generally uses platinum as a catalyst, and the working environment temperature is generally 60℃-80℃, which is a low-temperature fuel cell.

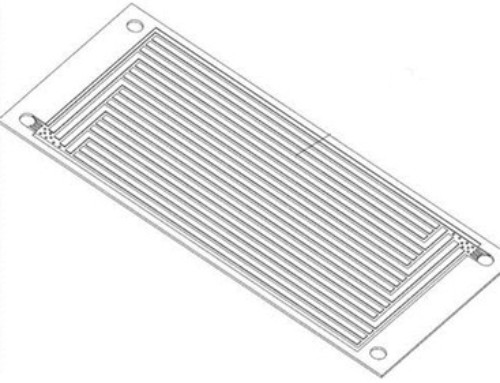

The proton exchange membrane fuel cell unit is mainly composed of membrane electrodes, sealing rings, and flow field plates with gas channels. The membrane electrode is the core part of the proton exchange membrane fuel cell. In the middle is a very thin membrane-the proton exchange membrane. This kind of membrane does not conduct electrons and is an excellent conductor of hydrogen ions. It also acts as a diaphragm to isolate the two-pole reaction gas. The two sides of the membrane are gas electrodes, which are composed of carbon paper and catalyst. The anode is a hydrogen electrode and the cathode is an oxygen electrode. The flow field plate is usually made of graphite. Proton exchange membrane fuel cells use hydrogen as fuel. Multiple battery cells are connected in series or in parallel as required to form battery packs (stacks) of different power.

How to prepare high-quality membrane electrodes for proton exchange membrane fuel cells?

Cheersonic has committed to the research and development of various ultrasonic equipment for more than ten years. UAM4000L, UAM6000 and UAM8000 developed by our company is basic , programmable micro material spray coating system. Various types of catalysts suspensions including the carbon black ink , PTFE binder, ceramic slurry, platinum and other precious metal can be sprayed by using this bench-top ultrasonic spraying system capable of programming and controlling x, y, z three-axis coordinated operation are deposited onto PEM fuel cells, GDL, electrodes, electrolyte membranes and SOFC to create maximum load and high cell efficiency. Precise and controllable liquid supply system compared with different types of customized nozzles, significant reduction in materials usage and producing the highly uniform durable, repeatable and durable coatings from R & D to medium-sized batch production. The body is small and easy to place, the spraying performance is stable, and the operation is convenient.

Cheersonic is a professional manufacturer in the development and application of liquid ultrasonic atomization technology into nozzle systems and spraying and coating application systems. Compared to conventional pressure spraying methods, the company’s ultrasonic nozzles do not clog, reduce liquid usage, waste, and environmental impact while achieving much more precise, uniform, thin film coatings. Cheersonic is continually developing new applications for its unique technology, replacing wasteful practices in a world that is growing ever more environmentally sensitive.