Project Description

Prism Spray Coating System

Heated Vacuum Chuck Provides Flexibility to the Prism Spray Coating System

CHEERSONIC, the leading manufacturer of high-performance ultrasonic spray coating equipment for the solar, semiconductor, and fuel cell markets, announces the availability of a heated vacuum chuck option for the Ultrasonic spray coating system.

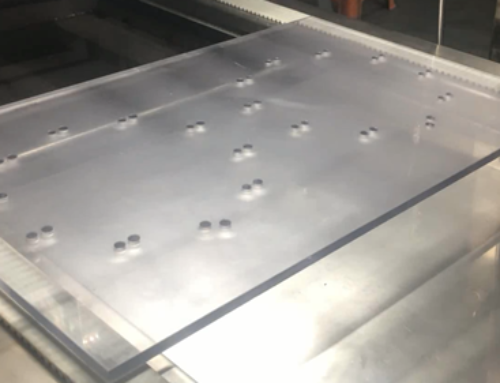

The heated vacuum chuck option for UAM6000 is ideal for thin substrate, wafer, foil, and membrane coating applications, where it enhances control of the substrate to achieve the desired coating thickness and uniformity. The heated vacuum chuck can be programmed to heat the substrate up to 150 degrees Celsius. Available in two (2) size options for various requirements, the vacuum chuck features a sintered aluminum chuck plate for an even vacuum draw across the entire chuck surface. Vacuum is supplied via an integrated venturi vacuum generator.

The flexible and highly configurable ultrasonic spray coating system is ideal for both production and R&D applications within the semiconductor, fuel cell, and electronics assembly markets. All ultrasonic systems leverage Cheersonic’s nozzle-less ultrasonic spray head technology providing material transfer efficiency up to 99%.

Ultrasonic Spray Coating System Video

Recommended Equipment

Ultrasonic Atomization Nozzle

Laboratory Ultrasonic Coating System

UAM3000 Ultrasonic Medical Devices Spraying

UAM4000 Desktop Ultrasonic Spraying Equipment

UAM6000 Ultrasonic Spraying Machine

UAL100 Ultrasonic Dispersion Syringe Pump

LULP500 Ultrasonic Laboratory Device

Prosonic1000 Industrial Ultrasonic Device

Prosonic3000 Most Powerful Ultrasonic Processor