Project Description

Photoresist Coating

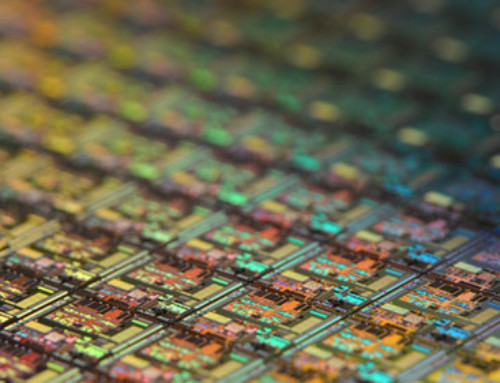

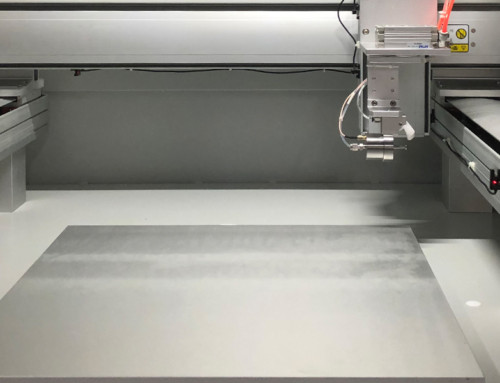

Cheersonic provides unique ultrasonic spray coating technology for semiconductor photoresist coating, with the advantages of high uniformity, excellent wrapping for microstructure and controllable coating area compared with traditional coating techniques such as spin coating and dip coating. In the past 10 years, it has been proved that the photoresist coating for 3D microstructure surface prepared by ultrasonic spray coating technology is significantly superior than that prepared by conventional spin coating technology in terms of microstructure wrapping and uniformity.

Cheersonic’s ultrasonic photoresist coating system can be applied to surface coating of materials including silicon wafers, glass, ceramics, metals, and 3D base materials. The photoresist coating is typically applied in wafers, MEMs, lenses, microfluidic chips and filters, etc. Ultrasonic spray coating is a simple, effective and economical solution for photoresist coating.

The ultrasonic spray coating system of Cheersonic can control the spraying flow, coating speed and loading amount excellently. Extremely low carrier gas flow rate ensures the accuracy of the spraying area and avoids the problem of over spray to a large extent. Ultrasonic spray coating could achieve more than 4 times the utilization rate of raw materials compare with conventional air spray coating.