Project Description

Ink and Inkjet

Ink can be a complex medium, composed of solvents, pigments, dyes, resins, lubricants, solubilizers, surfactants, particulate matter, fluorescents, and other materials. The components of inks serve many purposes; the ink’s carrier, colorants, and other additives affect the flow and thickness of the ink and its appearance when dry.

Ink and Inkjet Dispersion Results

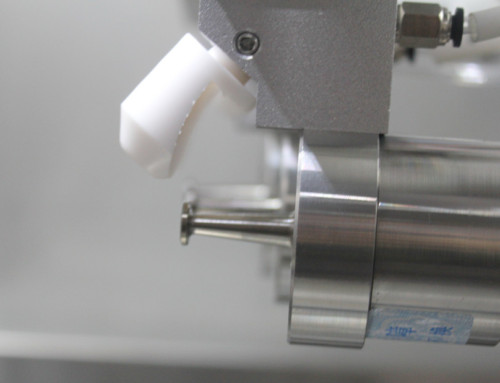

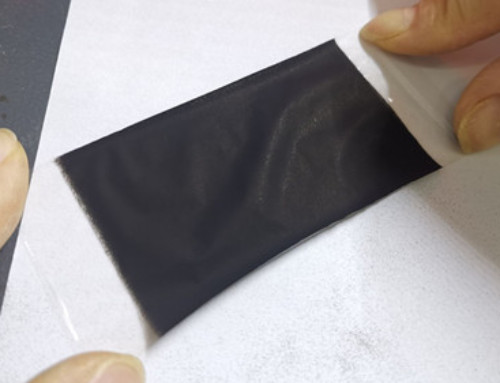

CHEERSONIC is developed by ultrasonic dispersion equipment to promote the production of printing ink, ultrasonic dispersion equipment, as a kind of physical means and tools, the ability to produce a series of chemical reactions are commonly used in the medium of close to the extreme conditions, such as instant high temperature and high pressure, the energy in the material chemistry plays a light, electricity, heat method cannot reach. Ultrasonic dispersion equipment cavitation and mechanical mixing crushed, ink particles will be easier to achieve a narrow distribution of mesoscopic mixing required, remove the uneven local concentration, as well as the ink aggregate can also play a role of shear.

The Effect of Ultrasonic Dispersion Machine

CHEERSONIC research and development of ultrasonic dispersion equipment compared with the traditional method, ultrasonic dispersion equipment has effectively control ink particle size and shape, to accelerate the mass transfer rate, accelerate the reaction rate, mild reaction condition, high yield, and the advantages of convenient operation and economic and efficient, and the product has high purity, narrow particle size distribution and uniform form, preparation of nanoscale ink has become a kind of effective means, and is suitable for promotion to the large-scale industrial production, in the field of printing ink preparation and showed good development momentum and broad application prospects.

Ink and Inkjet Dispersion Video

Standard Unit Ultrasonic Sonochemistry Solutions

Standard -Ultrasonic Sonochemistry Horn

Standard -Ultrasonic Generators

Automatic-Ultrasonic Liquid Processer Solutions

Prosonic1000 Ultrasonic Liquid Processer

Inline Ultrasonic Liquid Processer Solutions

Inline -Ultrasonic Liquid Processer