Project Description

Anti-Reflection Glass

In hot climates, Anti-Reflection glass can be used to minimize solar heat gain and help control glare. The design and placement of glass, known as fenestration, in specific areas of the building crafts the best environment for energy efficiency. In temperate regions, it can be used to equalize solar control with high levels of natural light. In more serene climates, architects employ operable windows as a cost-saving substitute to air-conditioning.

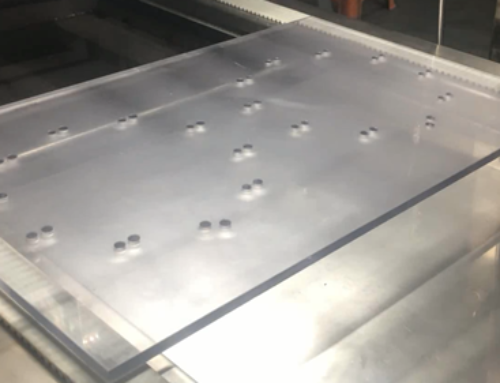

Anti-Reflection Glass Results

CHEERSONIC use self-developed ultrasonic spray equipment, through experiments proved capable of producing high-quality glass anti-reflection film. After instrumentation, the results showed that the visible light transmittance of 85%, the infrared cutoff wavelength of 1800nm, resistance of 2 megabytes per cubic centimeter or less, an average particle size of 50nm.

The Effect of Ultrasonic Spraying Machine

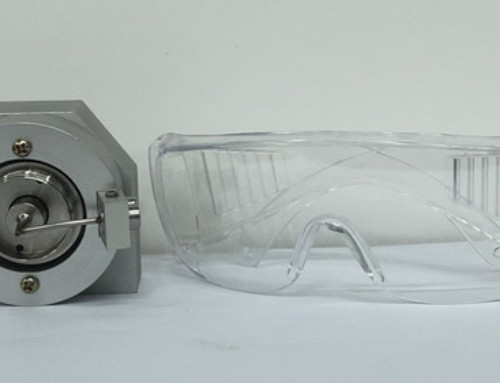

The non-clogging nature of ultrasonic nozzles, the small and uniform droplet size created by them and the fact that the spray plume can be shaped by tightly controlled air shaping devices make the application quite successful in wave soldering processes. The viscosity of nearly all fluxes on the market fit well within the capabilities of the market. Contact CHEERSONIC today to test spray your products on our ultrasonic atomization spraying equipment.

Anti-Reflection Glass Spraying Video

Standard Unit Spraying Solutions

Standard -Ultrasonic Nozzle

Standard -Ultrasonic Generators

Automatic-Production Spraying Solutions

Automatic–UAM3000 Ultrasonic Spraying Machine

Inline Spraying Solutions

Inline Ultrasonic Spraying Machine