Project Description

Overview of Handheld Ultrasonic Spot Welding

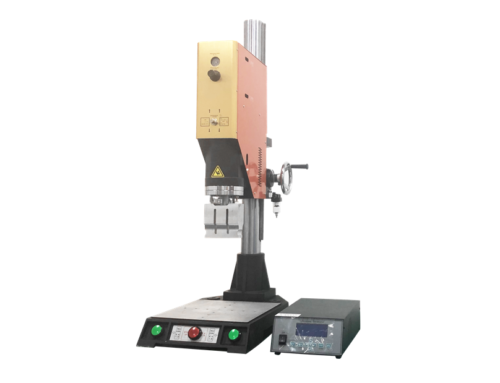

Ultrasonic spot welding machine can be used for butt welding of thermoplastic, can also be replaced according to customer needs welding head, for welding, spot welding, embedded, cutting and other processing technology, compared to other traditional processes (such as adhesive, Fastening, etc.), with high production efficiency, welding quality, environmental protection and energy saving and other significant advantages. Through the welding of ultrasonic energy to the welding area, due to the welding of the two joints at the interface of large resistance at the interface, it will produce local high temperature. And because of poor thermal conductivity of plastic, the moment can not be distributed in time, gathered in the welding area, resulting in two plastic contact surface rapid melting, coupled with a certain pressure, to integrate into one. When the ultrasonic stops, let the pressure last for a few seconds to make it solidified, thus forming a solid molecular chain, to achieve the purpose of welding, welding strength can be close to the strength of raw materials.

Principle of Handheld Ultrasonic Welder

Ultrasonic welding machine welding principle is generated by the generator 20KHz (or 15KHz) high-pressure, high-frequency signal, through the transducer system, the signal is converted to high-frequency mechanical vibration, added to the plastic workpiece, through the workpiece surface and internal The friction between the molecules and the temperature of the transfer to the interface, when the temperature reaches the melting point of the workpiece itself, so that the workpiece interface quickly melt, and then fill the gap between the interface; when the vibration stops, the workpiece at a certain pressure Cooling stereotypes, it will achieve the perfect welding.

Ultrasonic Spot Welder Application

Portable spot welding machine is widely used in the apparel industry, the trademark industry, the automotive industry, plastic electronics, household goods industry.

Clothing industry: underwear pants needle before the process, the ribbon elastic belt welding; can be used for point drilling.

Trademark industry: weaving Mark with, India-Mark, and so on.

Automotive industry: door noise cotton, wiper seat, engine cover, water tank cover and so on.

Plastic electronic: small plastic pieces riveting and so on.

Household goods industry: fiber cotton spot welding and so on.

Advantages of portable ultrasonic welding machine

Hand-held ultrasonic welding is a fast, clean, safe and other advantages of plastic parts to achieve the advanced technology, the use of Japanese components, force large-scale reliable; multiple protection circuit for enterprises to provide efficient welding methods to reduce production costs.